ACE has a global reputation for world-class manufacturing, and this is a title we are justifiably proud of and work hard to maintain.

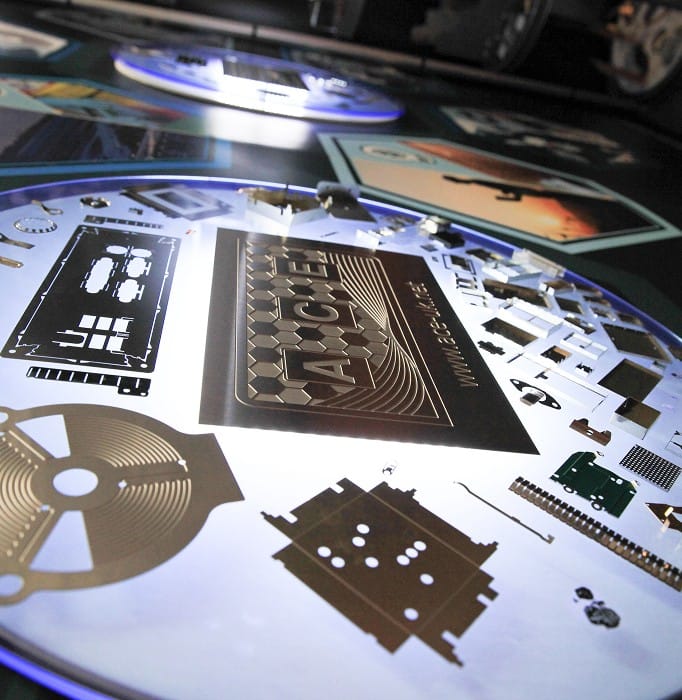

Our proactive management team encourage a culture of continuous improvement right across the business, and investment has flowed into implementing a best-in-class precision etching facility.

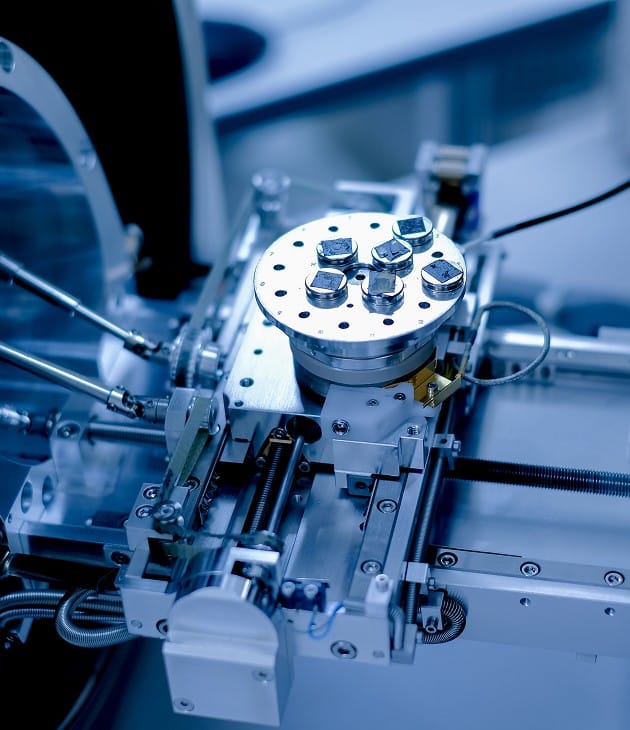

Responsive, Agile & Innovative

This makes us responsive to fluctuating demand, agile enough to take on new product introductions and innovative in our ability to deliver engineering solutions to complex problems.

Unrivalled Quality

All of this is done against a firm commitment to unrivalled quality, demanding tolerances and cost reductions for our wide and varied customer base.

Precision photo etching is a good alternative to stamping, punching, laser and waterjet cutting.

Because the photo etching of precision, micro-sized parts does not create burrs, stress or distortion.

Producing parts in a wide range of metals. ACE offers stainless steel etching, aluminium etching, titanium etching, copper etching, etching of nickel alloys and a wide range of advanced alloys.

The photo etching process is ideal for safety-critical parts and camera parts all having zero surface imperfections.