Aluminium Etching is the process of using an acid etchant to selectively dissolve away the metal until a crisp, burr-free component is left. Aluminium etching is quicker, safer and more controllable than traditional milling techniques, with components exhibiting higher definition features that are not possible to produce using other technologies.

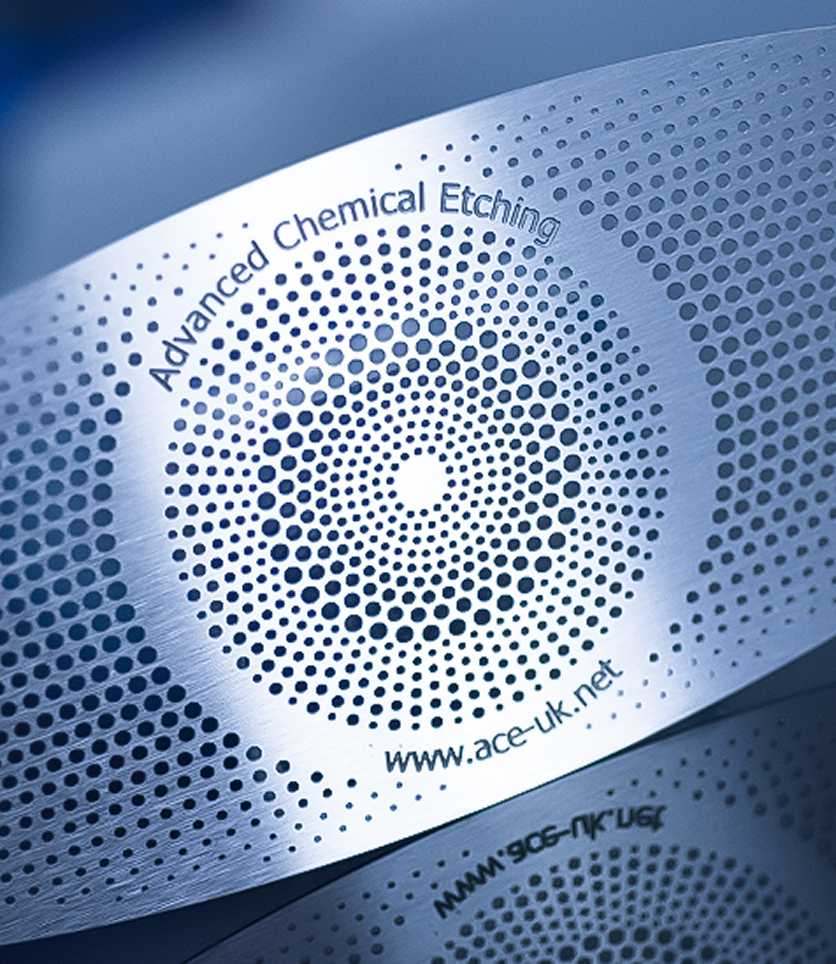

ACE have developed an aluminium etching process which produces high-quality etched aluminium parts both dimensionally and with excellent cosmetic appearance, a process that is highly consistent and capable of serial production volumes.

Aluminium etching is now used in full production to etch thousands of aluminium parts daily, and through continuous improvement work over the years controlling and certifying the aluminium etching process, the capability & capacity has now reached a very high level achieving some stunning results.

Precision Without Stress Or Distortion

Aluminium and its alloys are increasingly prized in engineering for their lightweight durability that enables energy saving. However, they are generally considered to be difficult, slow and inefficient to perform aluminium etching using conventional chemistry. Consequently, many users resort to punching, stamping or laser cutting to produce profiles but this comes at cost... stressing and heat distortion of the metal and the production of burr edges that have to be removed in a separate process.

Unique Aluminium Etching Process

With the introduction of this unique aluminium etching process ACE has a proven production route that is not only far quicker but also safer, and more controllable than the aluminium etching industry standard. It produces higher quality etched aluminium components with burr-free, crisp edges and higher definition features that cannot achieved using the industry standard aluminium etching technology.

An Optimised Solution

ACE first developed the new aluminium etching process in its R&D laboratory in 2012. This was then followed by extensive pilot-scale trials aimed at optimising the parameters of the new chemical etching solution. The ACE aluminium etching process is more controllable and more consistent than the industry standard, and produces etched aluminium parts that meet much higher quality standards each time, every time.

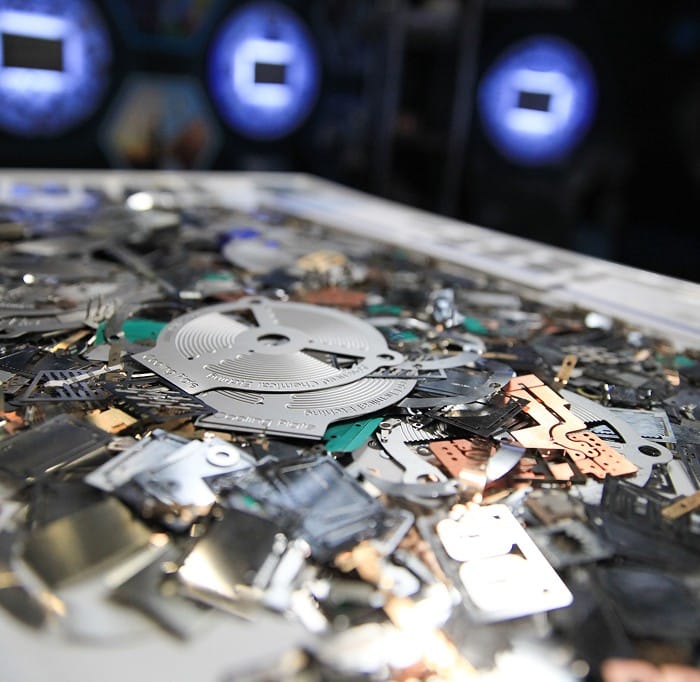

ACE is the UK's leader in aluminium etching, with millions of components etched every month. ACE is capable of producing precision metal components in all aluminium grades, at higher volumes and with shorter lead times. Aluminium etching from ACE means higher precision tolerances, complex geometries, and smooth, burr-free surfaces - suitable for precision engineering and lightweighting applications in the aerospace, automotive, and EV sectors.

While the conventional, industry-standard process of aluminium etching suffers from several serious drawbacks that make the process inconsistent and unreliable for large volume production. ACE has developed its own aluminium etching process that overcomes this problem.

Some of the benefits of our unique aluminium etching process include:

and smooth surface etch profile

±10% of material thickness

aspect ratio possible

up to 1500mm x 600mm

at no extra cost

aspect ratio possible

Etched Aluminium Channels

Etched aluminium components are lightweight and perfect for a range of precision engineering applications. Thanks to aluminium’s lightweight structure, the material is highly suitable for use within heat exchangers, cooling and bipolar plates, vital components in the development of next-generation electric vehicles. Extremely precise channels can be etched in aluminium using ACE’s aluminium etching process, which unlike stamping or other manufacturing methods, does not result in burrs or heat stress.

Want to discover aluminium etching for yourself? Experience the quality first-hand with a FREE sample pack.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.