Acid Etching is defined as the process of cutting a hard surface, such as metal, using a specially formulated acid for etching (etchant) in order to create a design on the metal. Find out more about how ACE produces acid etched metal components in our acid etching guide.

In this fast-moving manufacturing age, ACE has a proven track record of developing precision acid etched components. We are constantly developing new, innovative acid etching techniques and improving the formulation of our acid for etching. ACE manufactures millions of components each year, using our unique process to acid etch metal components. Our process can be applied to 2000 different metals in thicknesses of five microns to 2.5mm. Our team of technical experts are ready to advise on standard products for your sector or bespoke components that meet a specific technical application.

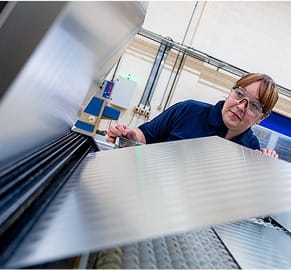

Discover the steps ACE uses to acid etch metal components from start to finish. ACE acid etch millions of components every month in a huge range of metals at higher volumes than our competitors. We are the UK's leader in acid etching stainless steel, titanium, and specialist metals in thicknesses ranging from 0.005mm to 2.0mm. Follow along as we walk you through the production process for acid etching on metal.

The Acid Etching Process

The acid etching process allows both surface etched detail and cut through areas to be produced at the same time onto metal thicknesses up to 1.5mm.

Etched Raised Areas

Alternatively, surface etched raised areas are produced by applying etching acid to one side only… an example is the manufacture of metal etched paper dies.

Metal Surface Etching

Etching detail can also be etched into the metal surface only… for uses such as etched presentation plaques or etched signage.

To Bear In Mind…

Unfortunately we are not able to put designs onto finished metal components or shaped metal items. Etching metal is performed by applying etching acid to perfectly flat sheets of metal. Please also note we are only able to acid etch metal.

The ACE acid etching process is more controllable and more consistent than the industry standard, and produces parts that meet higher quality standards each and every time.

What Are The Benefits Of Acid Etched Metal Components?

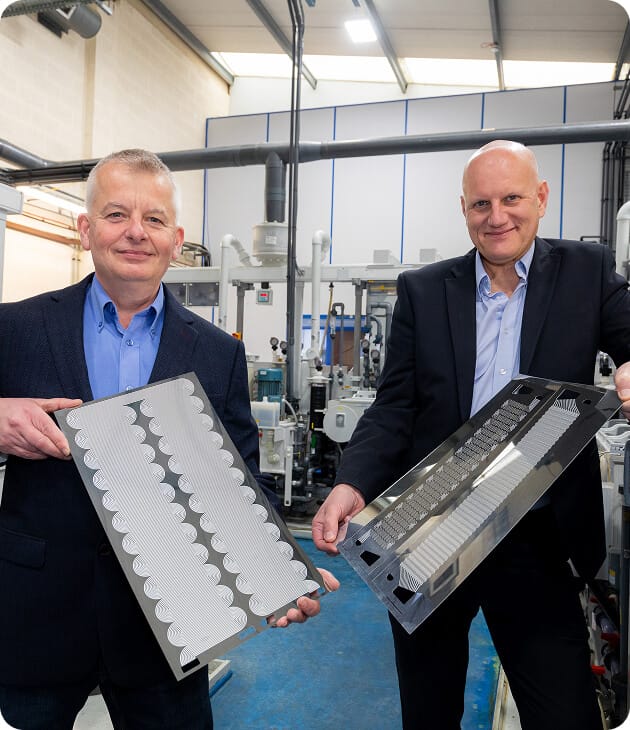

Acid etched metal parts are highly precise, have no surface defects such as burrs or heat stress and can be produced in large quantities very quickly. ACE has pioneered its own acid etching processes and formulated its own acid for etching. These are more controllable, quicker and safer than the industry standard. ACE produce a wide range of metal components using processes including acid etching stainless steel, titanium aluminium and copper to name a few, with very tight tolerances, crisp edges and higher definition features than our competitors.

Discover the benefits of acid etched metal components for yourself – request a free sample pack today.

ACE is the market leader in acid etching metal, and has pioneered many of the techniques that make acid etching on certain metals possible. These new processes allow ACE to etch even finer line micro channels and rapidly profile acid etched metal for customers involved in producing components for a variety of industries.

Stainless Steel remains one of the most popular metals ACE produce acid etched components in, due in part to is outstanding corrosion and oxidisation resistance. Acid etching Stainless Steel can produce multi complex profile shapes with burr-free edges - no finishing required. This material's versatility makes etching Stainless Steel a valuable process for a wide variety of industry sectors.

Titanium is renowned for its strength and high-temperature performance, however, using etching acid on Titanium is difficult due to the oxidised coating that forms when exposed to air. ACE is the first acid etching company to develop a unique, safer etching acid for etching Titanium, and is one of the few acid etching companies that have production capacity for etching Titanium.

ACE can etch a number of innovative materials. We have developed our own processes for etching Copper, Nitinol, Elgiloy, Iron and Nickel to name a few. Please contact our team if you have a project that requires a metal type you do not find on our site - we will always do our best to accommodate your specification.

Aluminium and its alloys are prized in engineering for their lightweight durability that enables energy saving - however acid etching Aluminium has generally been considered a difficult and slow process using conventional chemistry. ACE have pioneered a unique process for etching Aluminium that is safer and more controllable than the industry standard.

The Chemistry Of Etching Acid

At ACE, our preferred etchant (etching acid) is Ferric Chloride (FeCl3). Acid etching metal can be traced back as far as 1531, when the French scholar Jehan le Begue wrote a recipe for etching on iron, formulating acid for etching by distilling ammonium chloride, ordinary alum, and ferrous sulphate in a mixture of water and vinegar. Now ACE produces acid etched metal parts in a large variety of materials, and has pioneered new processes for acid etching Stainless Steel, Titanium, Aluminium, and much more.

Want to learn even more about the chemistry behind the etching acid we use? Read our white paper "How does acid etching work?".

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.