In May Advanced Chemical Etching continued its focus on growing and developing within both emerging and established markets. Read our May monthly news roundup to learn more about ACE’s latest activities.

This month our roundup focuses on the progress ACE has made in expanding its operations within the aerospace sector, including details of a new collaboration with international aerospace firm Collins Aerospace. In addition, May sees ACE acknowledged for its work within the medical sector during the COVID-19 pandemic, as well as a new drive toward chemical etching for EV.

ACE Going For Gold With Collins Aerospace

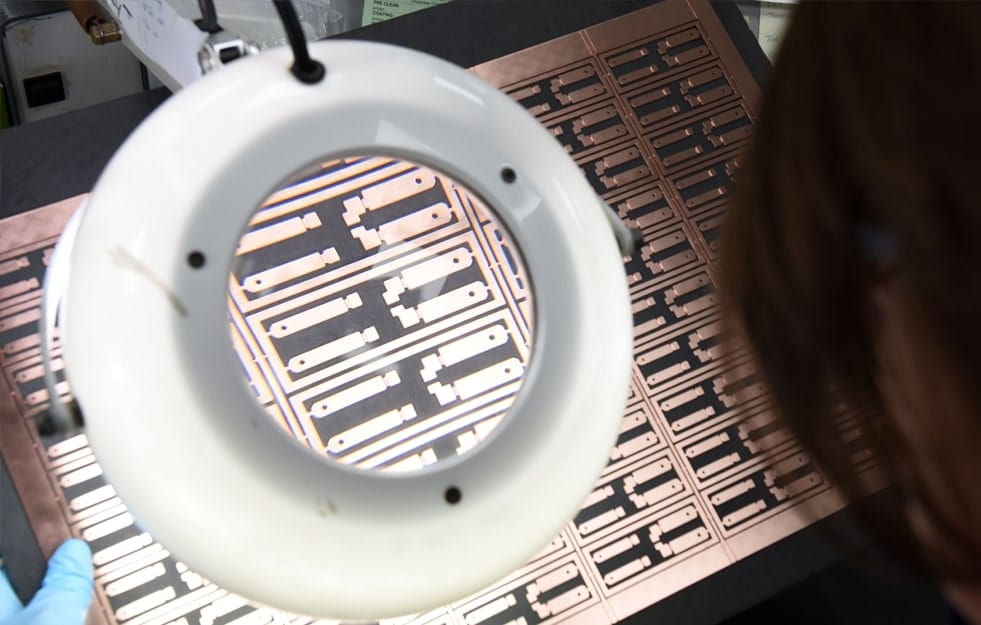

In May Advanced Chemical Etching announced they had joined a new supplier development programme headed by the aerospace and defence firm Collins Aerospace.

ACE will now take part in a programme of continuous improvement and training while continuing to supply the international firm’s group factories with high-quality precision etched components.

Ian Whateley, Managing Director, attributed ACE’s selection to take part in the programme to an already strong relationship with Collins Aerospace.

“This is a very demanding supplier development programme and very difficult to get on to, so this in itself is testament to the relationship we currently have with Collins Aerospace.”

“We have taken a top-down approach to our involvement, making sure every member of our 65-strong workforce is on board, understand what is required and how they can play a role in helping us achieve the performance requirements in terms of cost, quality and delivery.

Over the next six months, ACE will work to secure ‘Gold Supplier’ status, meeting 100% delivery on-time-in-full targets and collaborating closely on root cause analysis.

“Achieving Gold Supplier status will be huge for ACE. It will mean we could be used by any international division across the group, not to mention the profile it will give us amongst the rest of the industry.”

ACE’s continued focus on investment, development and innovation at it’s Telford facility has meant that it is strongly positioned to offer superior capability and capacity to the aerospace sector, which now accounts for 25% of annual sales.

Richard Jones, supplier development manager at Collins Aerospace, acknowledged ACE’s team strategy as being key to their success.

“Ian and his team are fully engaged with the training I’ve helped provide and this has ensured the right culture is in place, where a ‘Quality First’ mentality is embraced and driven by every single member of staff.”

“The company is well on its way to achieving the Gold Supplier status and, importantly, become ‘best in process’ across the etching world.”

Engineering Heroes Continue Fight Against COVID-19

ACE has been named among a number of UK-based engineering companies and organisations involved in and supporting the fight against COVID-19.

Engineering Heroes is a campaign to publicise UK engineering’s contribution to public safety and national recovery in the wake of the ongoing pandemic.

The campaign highlights the people, companies and technologies that have made a contribution during this time, including bolstering the supply chain of medical equipment and offering resources and support to the UK manufacturing sector.

Earlier in May ACE was acknowledged for its part in addressing the need for more medical ventilators via the UK Ventilator Challenge.

ACE is a key supplier to the medical sector, helping to drive innovation and the development of new advances in the field of medical devices.

Central to this has been ACE’s development of a new, safer and more reliable method for etching Titanium and its alloys, crucial for the production of intricate medical devices with complex mesh patterns or micro-etched channels.

From June 30th to July 2nd 2020 ACE will be taking part in MedtecLIVE’s virtual event, where the latest developments in chemical etching for the medical sector will be showcased. In the coming weeks, details of how you can watch ACE’s online exhibition will be published — be sure to stay tuned to the news page and social media for more information about this and other upcoming events.

ACE Continues Focus On EV Sector

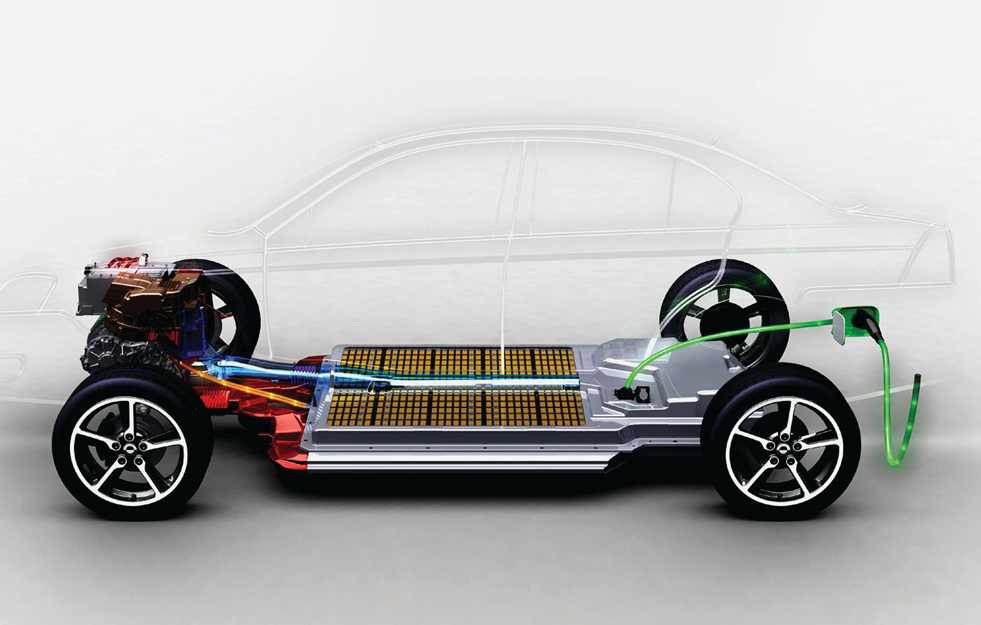

ACE is continuing to develop new manufacturing processes to support the needs of the EV sector and innovation within Electric Vehicle manufacturing.

Our recently launched EV page goes into further depth about chemical etching for EV, including the ways in which etching overcomes the challenges and limitations of heat-based cutting and fixing methods.

ACE produces a number of critical components for the EV sector including heat exchanger plates, heat shields, battery contacts and much more. Thanks to a continued programme of R&D and the development of new etching techniques, these components can be lighter, more intricate and more cost-effective to produce in high volumes, essential factors as Electric Vehicle manufacturers look to increase the range and efficiency of next-generation vehicles.

In May the Vehicle Electrification Expo announced new dates for its 2020 exhibition, now taking place on the 2nd and 3rd of December. The ACE team is looking forward to exhibiting and meeting with industry colleagues and clients soon. For the latest news and information about upcoming events and exhibitions from ACe make sure you’re subscribed to our monthly newsletter.

Read our new Electric Vehicle Technical Insert for more information on chemical etching for EV and the secondary operations offered by ACE.

No matter your requirements, our expert team will work with you to produce the high performance, lightweight and reliable parts you need. Contact ACE today on 01952 416666 or email sales@ace-uk.net for an initial consultation.