Advanced Chemical Etching – April 2022 Roundup

Published on 29/04/2022

Read on in our April roundup to learn more about how ACE is working with its clients and suppliers to ensure the stability of component manufacturing and supply. Also: the sales team gears up for an important event in the battery tech and EV industries’ calendar, and how you can judge the quality of ACE’s chemically etched components for yourself with our free sample pack.

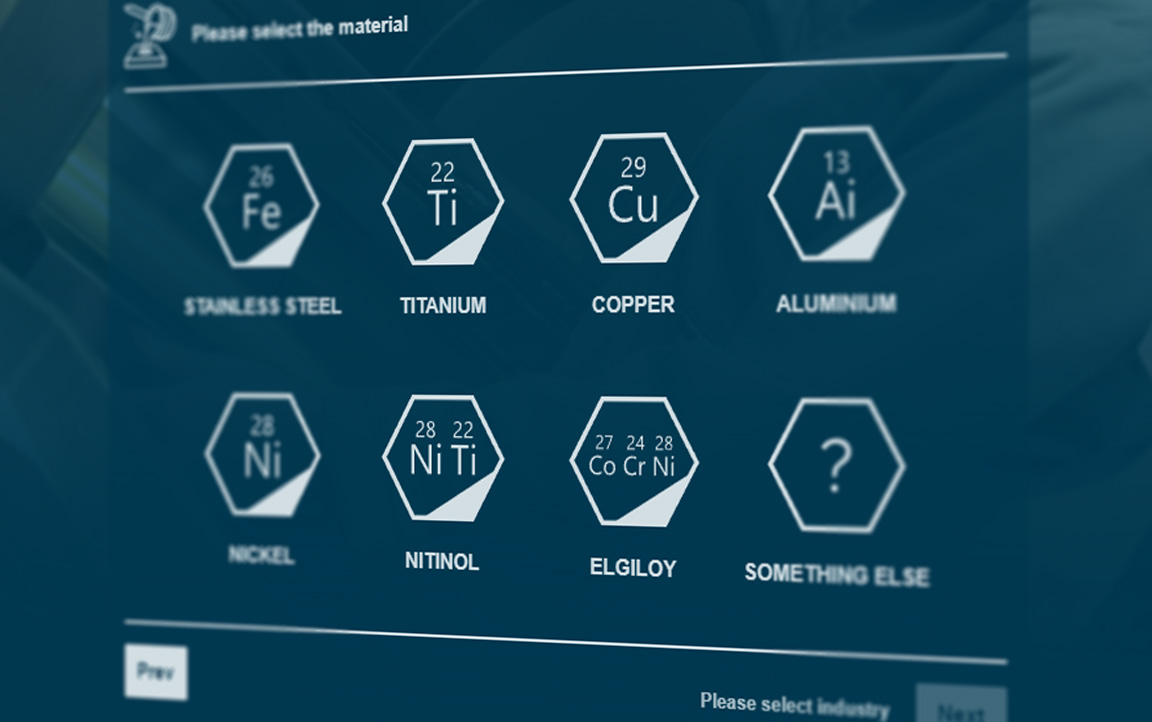

Discover ACE’s Advanced Ordering Tool

ACE has launched a new Advanced Ordering Tool, designed to assist customers in communicating their component manufacturing needs in advance, helping to ensure an uninterrupted supply of critical components.

The new Advanced Ordering Tool makes it easy to notify ACE of any component supply need – whether this is in the short term as part of an imminent manufacturing requirement, or prospectively, with support for projects into the medium-term.

The new tool is linked directly to ACE’s customer service team, who are on hand to assist and liaise with customers about their requirements, informed by information gathered by the simple feedback form.

While the tool presents a useful new channel for customers to make their upcoming supply needs known, it is not intended to replace any existing communication method. You can always get in touch with the team directly using our contact form, via email or by calling us on 01952 416666.

This comes as ACE continues to work to ensure the stable provision of precision metal components during a period of volatility within the worldwide metals market. Last year the team launched a supply security strategy, with proactive communication at the heart of our efforts to ensure the stability of our operational capacity.

By opening a channel with customers early and gaining advanced insight into our client base’s manufacturing needs, the team aims to ensure strategic blanket order cover is in place for key articles and to provide the same fast turnaround and superior precision at production scales.

The new tool can also be used to inform the team about any additional processes that may be required, such as forming, plating, and assembly.

Use our new Advanced Ordering Tool to inform our customer service team of a current or future manufacturing requirement. Need to speak to us directly? Get in touch with the team to learn more about our superior etching capability and discuss your project today.

The Team Gear Up For The Battery Tech Expo, 12th May 2022

The ACE sales team are gearing up for the Battery Tech Expo, which will be held on the 12th of May 2022 at The Wing, Silverstone Circuit, Towcester.

The Battery Tech Expo is a much-anticipated event on the calendars of both British and international engineering and manufacturing firms, showcasing the latest technologies

covering battery storage, battery management systems, lithium-ion batteries and much more.

Held at Silverstone, at the heart of British F1 and motorsport, the event is set to attract a wide variety of industry professionals within the battery technology and EV sectors and offers an excellent opportunity to learn about the latest developments the manufacturing, processing, and chemistry of innovative battery technology.

Advanced Chemical Etching will be exhibiting on stand 25 at the event, showcasing the latest in chemical etching and precision component manufacturing, and discussing the benefits of our innovative manufacturing process in the development of next-generation battery systems.

ACE plays a key role in driving EV technology, developing new processes to help overcome material limitations within EV components, and assisting in the development and production of modular systems within battery systems, including bus bars, heat exchanger plates, interconnects, and heat shields.

Because metal is removed locally, chemical etching equips EV designers with alternatives to fixing using laser welding, overcoming the challenge of heat damage within the cell. Chemical etching is also uniquely positioned to deliver the lightweighting benefits required by the most efficient battery systems.

The sales team will be on hand to liaise with attendees and help them discover how chemical etching can help meet their product development and manufacturing requirements.

Find Advanced Chemical Etching’s exhibition display at stand 25 on the 12th of May at The Wing, Silverstone. Can’t wait until then to discover how chemical etching could work for you? Get in touch with our team to arrange a meeting and discuss your requirements.

Discover ACE’s Precision Etched Components For Yourself

ACE’s sample packs are designed to help you gauge the superior precision and exacting tolerances of our chemically etched components for yourself.

We believe seeing is believing!

Order a free sample pack today and discover the difference ACE’s innovative chemical etching processes could make to your next project.

Choose from our full sample pack or our cooling plate sample pack tailored for the EV and fuel cell sectors.

Simply fill out a short form telling us where to send your pack, and we’ll pop it in the post. You’ll soon discover why so many precision engineering, medical, automotive and aerospace firms look to ACE for the highest quality, highest precision chemically etched parts.

No matter your requirements, our expert team will work with you to produce the high performance, lightweight and reliable parts you need. Contact ACE today on 01952 416666 or email sales@ace-uk.net for an initial consultation.