Advanced Chemical Etching – September 2022 Roundup

Published on 29/09/2022

Read on in our September news roundup to find out all the latest from the ACE team. Want to stay up to date with all the latest from Advanced Chemical Etching? Connect with the team on LinkedIn today and be part of the conversation. Or if you wish to enquire about your precision component etching needs, why not try our new enquiry tool?

New Growth Opportunities Etched In Metal As ACE Completes £500k Investment Drive

Advanced Chemical Etching has taken delivery of two Chemcut Etch machines at its Telford facility in a bid to meet increasing global demand from the aerospace, electric vehicle, and hydrogen fuel cell markets.

The acquisitions will increase the firm’s etching capacity by 30 per cent and will help customers bring their designs and prototypes to market quicker, a decisive selling point that the business hopes will help it meet its two-year plan to hit £10 million in sales.

It has been a busy 12 months for ACE, with turnover now back past Covid-19 levels and its best-ever month recently recorded after an influx of domestic and international orders were completed for customers keen to avoid international supply chain disruption.

Ian Whateley, managing director of ACE, said:

“We are always looking at ways where we can reduce lead times and have greater control over the tolerances we can offer, and this latest investment reinforces that.”

“The two etching machines are currently being installed and should be fully up and running by late summer. When they go live, we’ll have a third more production capability, which means we can go after new opportunities and there’s plenty of those currently, whether it’s supplying busbars and lead frames to EV or critical components to the medical sector.”

“This latest technology will make us faster, guarantee repeatable quality and, with energy costs rising, will reduce our electricity and water consumption considerably.”

ACE specialises in the development of precision components to customers in more than 25 countries, spanning aerospace, space, precision engineering, automotive, electronics, medical, EV and renewables.

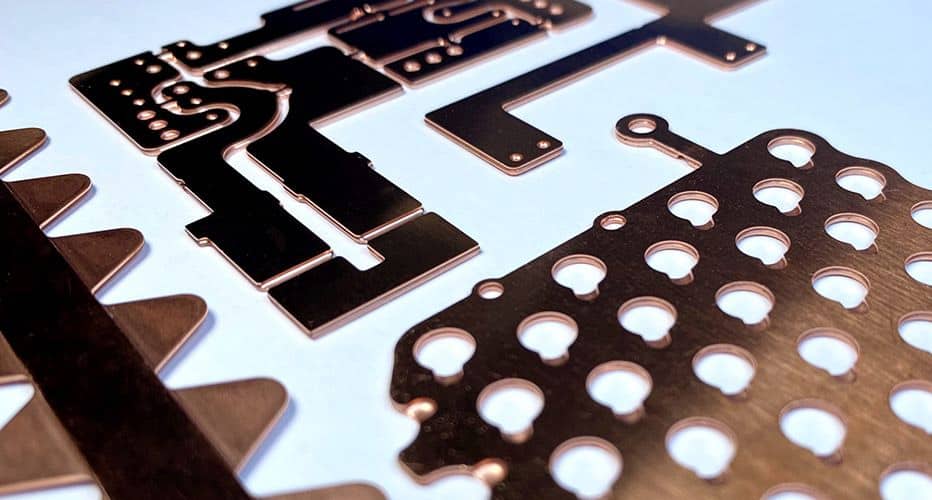

The scope of its activities is far and wide and can include anything from safety critical components for aircraft and F1 cars, to meshes and electronic connectors, battery interconnectors, fuel cell bi-polar plates, cooling plates and heat exchangers.

All parts are developed and manufactured at its main site in Telford or at the company’s dedicated sister business, ACE Forming Limited, in Kingswinford.

It works to the most exacting tolerances and can manufacture components in materials, such as stainless steel, nickel alloys, copper, beryllium copper, phosphor bronze, brass and, thanks to new processes, aluminium, molybdenum, titanium, nitinol and elgiloy.

Chris Ball, executive Director, added:

“We operated throughout the pandemic and, thankfully, have emerged with an even stronger order book than what we went into Covid-19 with… that’s a great position to be in, especially with the amount of reshoring opportunities heading back to the UK.”

“In addition to our recent investment drive, we have also strengthened our workforce with eight new people joining across our inspection, facility and plant maintenance, and our sales and marketing departments.”

“There has been an increase in the number of special operation products we are getting involved in and this would necessitate the need for people to be multi-skilled and internally work across numerous projects. That’s why investment in ongoing training will be so crucial.”

ACE is planning more exhibitions this year, with its next appearance coming at the Precision Fair in the Netherlands in November.

It is also seeing requests to do mini trade shows of its capability to many several design departments at existing and new customers.

Can’t wait to discover how chemical etching could work for you? Order your FREE sample pack today and get to grips with ACE’s precision chemically etched components for yourself.

Collaboration & Q&A Session With Batterydesign.net

Advanced Chemical Etching has recently collaborated with Batterydesign.net, a research and information resource developed by battery design engineers that aims to collate articles, posters and design information into one collaborative space.

Technical Sales Manager Gary Mariott sat down with Batterydesign.net for a Q&A session to discuss what makes photo etching so valuable to the battery tech and EV industries. Points discussed included the development history of the process and how ACE has taken this further to manufacture the most precise, high quality aluminium and copper parts, including busbars, cooling plates and interconnects.

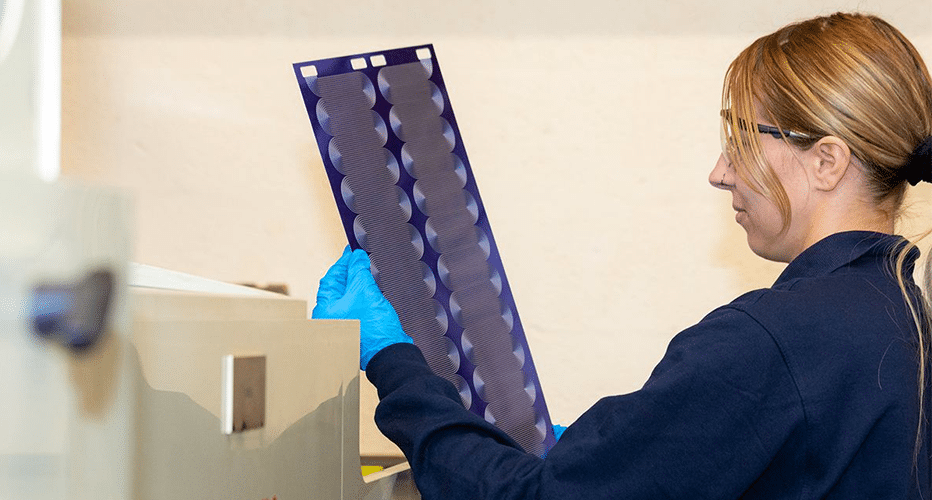

ACE has invested heavily in R&D, adopting a systematic, research-based approach, adapting the chemistry to suit the requirements of individual projects. A more precise, repeatable photo etching process means parts that do not exhibit the metal stress or rough edges of traditional stamping and cutting methods, leaving a part that is right first time and does not require secondary processing. This process is scalable and can rapidly produce parts at volume.

An additional benefit of photo etching relevant to the battery tech industry is the process’ ability to overcome heat fixing limitations, weight reduction and superior contact and conduction with the cell.

Read Batterydesign.net’s full photo etching article and Q&A over on their website and learn more about how photo etching from ACE is changing what’s possible for the EV and battery tech sectors. Want to discuss the applications for your project? Why not book a meeting with our technical experts to learn more.

Visit ACE’s New Exhibition At Precision Fair 2022

The sales team is gearing up for ACE’s first European exhibition since 2019, Precisiebeurs (Precision Fair) 2022 in Brabanthallen, ‘s-Hertogenbosch – The Netherlands.

Precision Fair is Europe’s premier gathering for the precision engineering supply chain, bringing together manufacturers, designers, research and knowledge institutes and over 300 specialised suppliers. Advanced Chemical Etching will be joining in on this 2-day event, exhibiting on stand 433 on the 16th and 17th of November, 2022 between 9:30 – 17:00.

Along with networking, conferences, panel discussions and product demos, Precision Fair is a great opportunity to learn more about the latest developments in precision engineering directly from industry experts. ACE’s technical sales team will be attending with their new exhibition stand, demonstrating chemical etching’s unique applications for a huge range of sectors.

Visit ACE at Precision Fair 2022 in November. Can’t make it to the event? Discover chemical etching for yourself with one of our FREE sample packs. Or if you’d like to discuss your chemical etching needs with our technical experts, contact ACE today on 01952 416666 or email sales@ace-uk.net for an initial consultation.