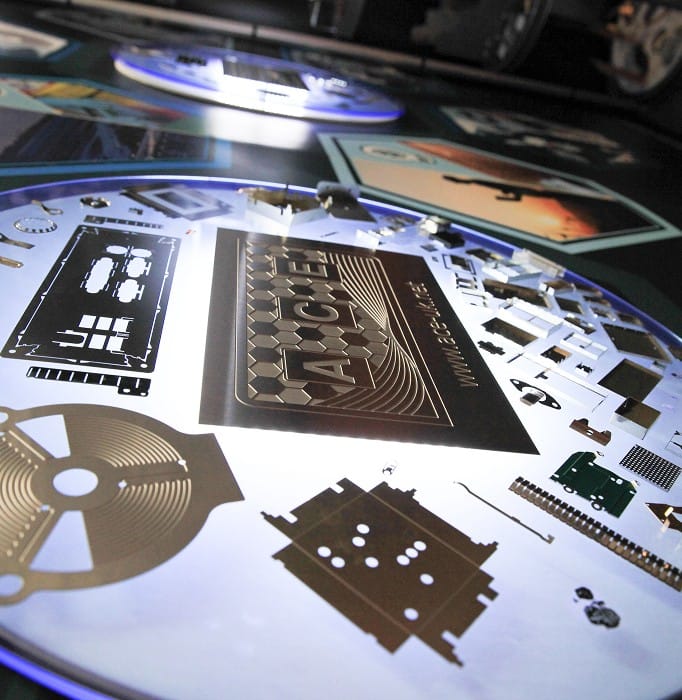

Quality, speed, precision and innovation are four of the key drivers that make ACE an instrumental partner to the Aerospace Engineering and Defence sectors.

ACE is your reliable source for quality aerospace parts etching. Lean manufacturing principles adopted in other sectors are now being embedded by the company in attracting and subsequently delivering a range of custom-made components for many different aircraft platforms.

Major Industry Partner For Emerging Technologies

Our growing reputation has seen us work collaboratively with many major aerospace firms, with an emphasis on helping them develop emerging technologies.

Aerospace parts etching is ideal because the process produces stress, burr and distortion-free components from design prototypes to full serial production.

Opportunities For Growth

An increasing move to miniaturisation of parts, alternative material usage and greater supply chain management all represent significant opportunities for growth in the coming years.

Etching is ideal for aerospace parts as it produces stress-, burr- and distortion-free components from design prototypes to full serial production.

The etching process can etch intricate and complex micro channels/features for heat exchanger shims/plates so that it maximises thermal efficiency and laminar flow. The channels are extremely accurate for both depth and channel width requirements.

Aerospace parts that require subsequent stacking, brazing or diffusion bonding use photo etched shims/plate, as the process produces flat plates with etched micro channels and the profiles are burr-free.