Advanced Chemical Etching (ACE), the Midlands-based etching specialist has developed new, safer chemistry that will take the etching of Titanium to new levels of quality and precision.

Titanium is renowned for its strength and lightweight properties but it is difficult to etch due to the fact that it rapidly forms a protective oxidised coating when exposed to air; a coating that is exceptionally hard to dissolve.

Traditionally, Hydrofluoric Acid (HF) has been used as the preferred etchant because of its ability to remove this oxide layer but it is a highly toxic material and one to be avoided if possible.

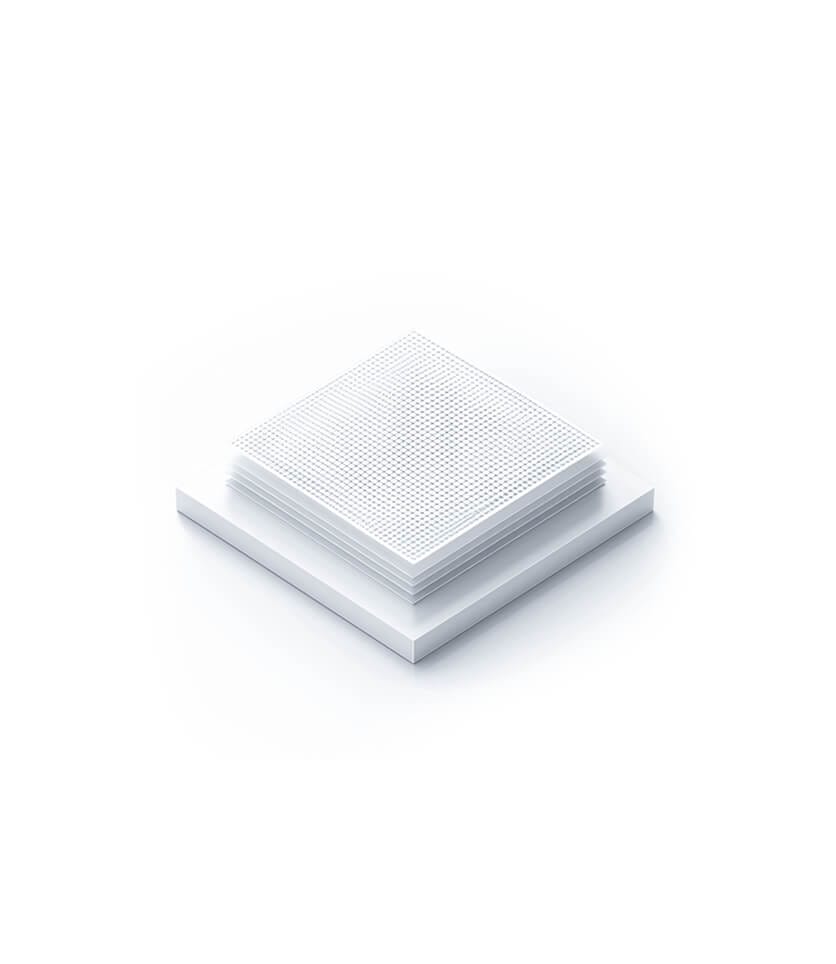

Through an extensive R&D programme, ACE developed a new process that is safer to use than the conventional Ti etching method. The new process, called Titanium Molecular Etching TiME, is also faster and more controllable, offering outstanding precision with sharp, well-defined features and crisp edges.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.