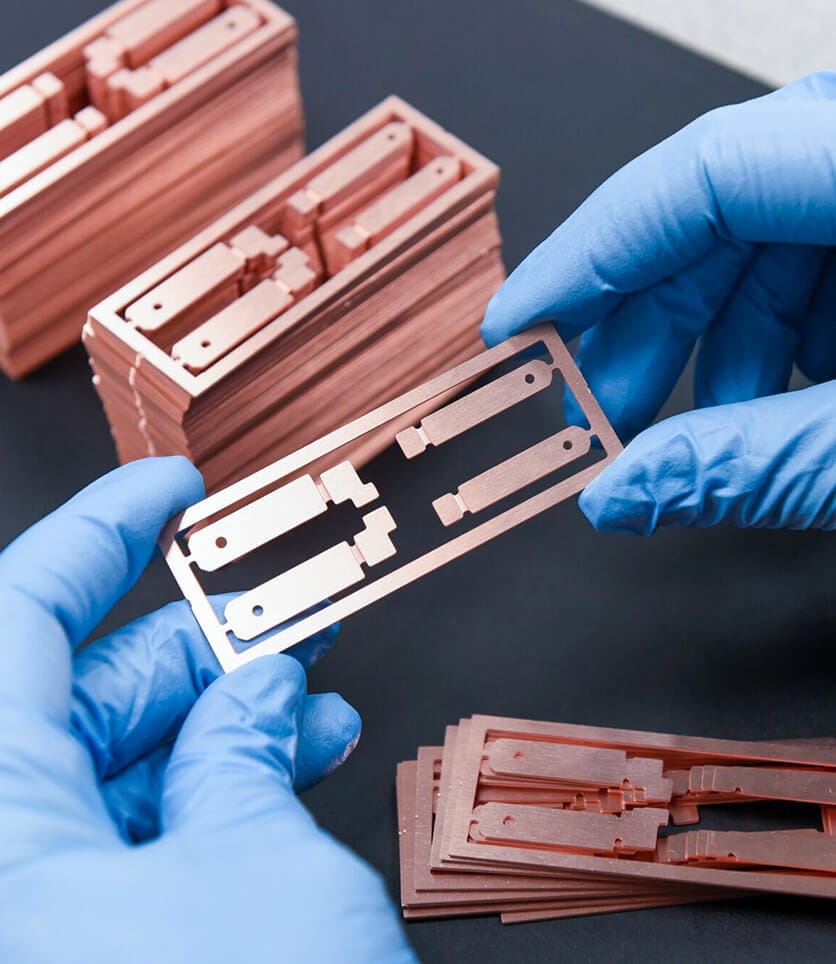

Copper Etching is the process of manufacturing complex metal components from copper or copper alloys using a chemical etching process. Corrosive chemicals are used to dissolve the metal until only the desired shape is left.

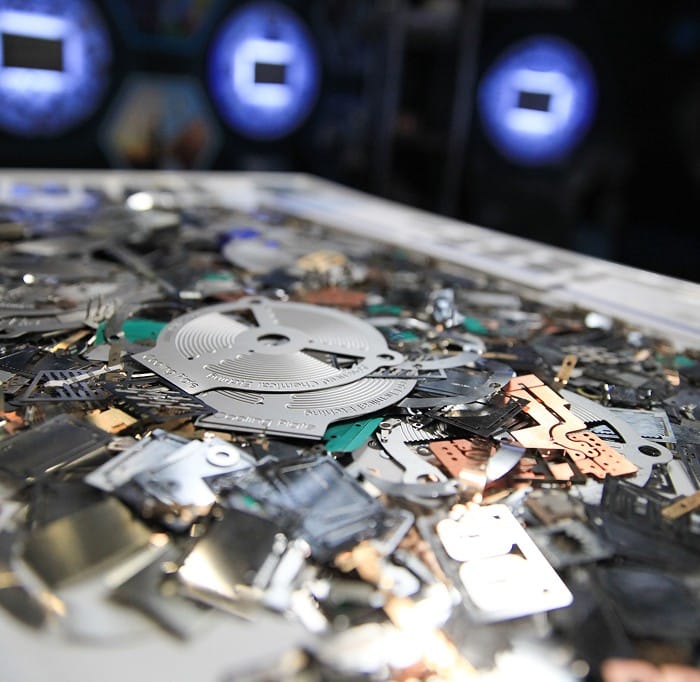

ACE is a market leader of precision copper etching; we acid etch copper at large volumes, producing millions of components each month using a wide variety of different grades, such as the brass, copper, phosphor bronze, nickel silver, cupronickels and beryllium copper.

Go-To Process

Low set-up costs and incredibly fast lead times make copper etching a go-to process in batch sizes of ones to millions.

Any Complexity

Component features are etched at the same time so part/feature complexity is not an issue. The complexity of the profile does not affect the price… to process thousands of apertures or just the one, the price remains the same.

Low Cost Tooling

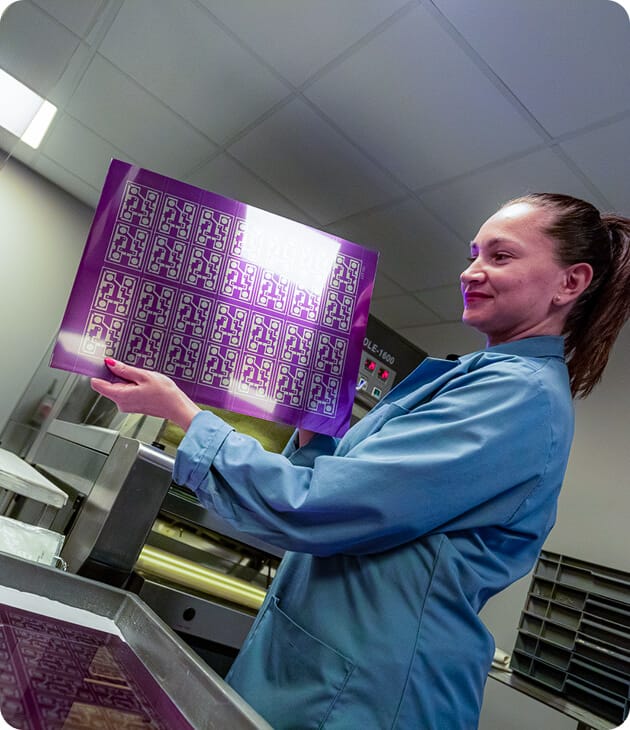

The tooling for copper etching and its alloys is digital, low-cost and can be modified quickly. Many customers select copper etching because of the flexibility it provides for supplying samples in days rather than weeks or months.

Right First Time

No heat or force is used when acid etching copper and its alloys, so the mechanical properties of the metal remain unaltered and parts are free from stresses and burrs.

Copper is an incredibly versatile metal with many excellent properties including good electrical and thermal conductivity and high resistance to corrosion. Some copper alloys, such as Beryllium Copper, exhibit incredible strength. Copper is also easy to form, making it the go-to metal for manufacturing components such as busbars, heat exchanger plates, conductive springs, and leadframes, components of particular importance to the development of products such as electric vehicles.

While the conventional, industry-standard process of copper etching suffers from several serious drawbacks that make the process inconsistent and unreliable for large volume production, ACE’s unique process overcomes this problem.

Some of the benefits include:

and smooth surface etch profile

±10% of material thickness

aspect ratio possible

up to 1500mm x 600mm

at no extra cost

from 0.07mm to 2.5mm

All Round Metal

Copper and copper alloys are an important group of metals with many excellent properties. They have good electrical and thermal conductivities, are easy to form and include some alloys with incredible strength (beryllium copper alloys) and corrosion resistance. The characteristics of copper alloys have meant that ACE acid etches copper for a wide range of parts for may different applications. They can be etched then formed or deep drawn into the most complex of shapes.

Multi-Purpose

Due to its versatility, copper alloys are used in a wide variety of products in many industry sectors. When parts are etched in any of the copper alloy the process will not affect the mechanical properties of the metal, meaning the metal remains unaltered by the process. Areas of the surface can be etched or reduced and the metal shows no distortion or warping. Multi complex profile shapes can be etched and the edges will remain burr free. ACE can acid etch copper in thickness of 0.005mm to 2.0mm in all copper alloys, in hardness’s from soft (annealed) to mill hard condition and to a maximum sheet size of 1500mm x 600mm.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.