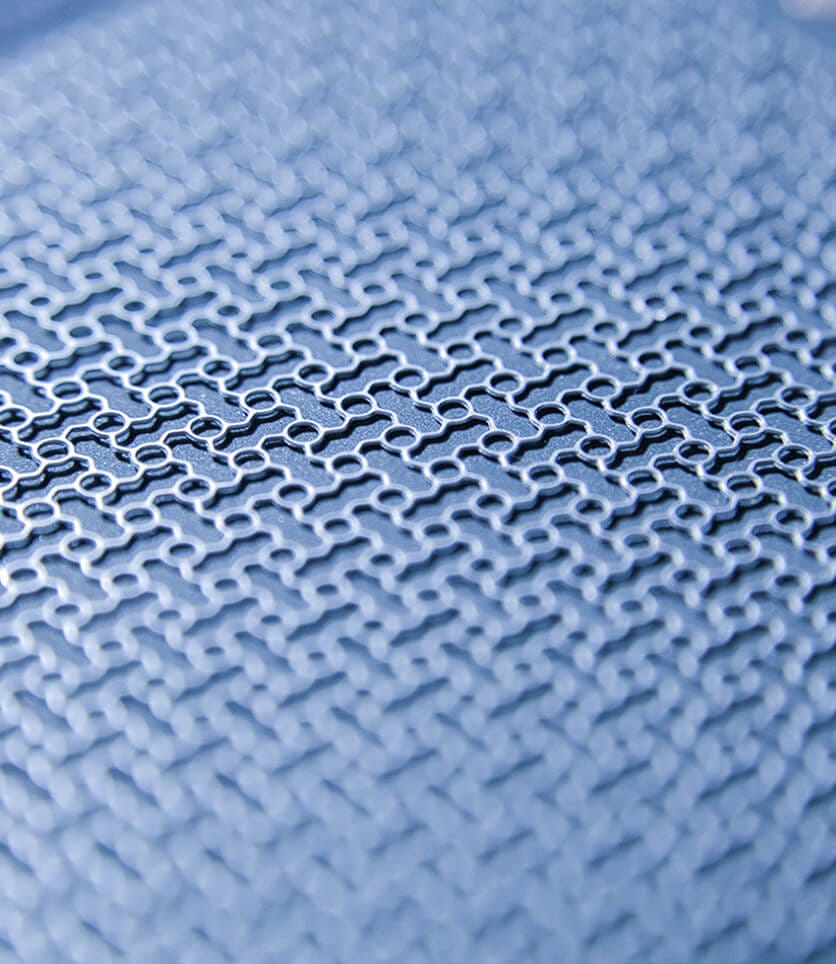

Titanium etching is the process of using an oxidising reagent to selectively dissolve away the metal. Titanium etching allows high volumes of intricate components to be etched in titanium at speed, without affecting the chemical and mechanical properties of the metal.

Titanium is renowned for its strength, light-weight properties and high temperature performance. However, chemically etching titanium is difficult because titanium rapidly forms a protective oxidized coating when exposed to air, a coating that is exceptionally hard to dissolve. Advanced Chemical Etching's unique TiME technique makes producing etched titanium parts possible at extremely tight tolerances. ACE has pioneered a unique process for acid etching titanium, making us the industry leader for this etched titanium manufacturing technique. Learn more about the titanium etching process below.

ACE is capable of producing precision metal components in all titanium grades, including Nitinol and Kapton Coated Titanium. Titanium etching from ACE means higher precision tolerances, complex geometries, and smooth, burr-free surfaces – suitable for applications in a variety of sectors, especially in the medical field, which has a high demand for lightweight etched titanium components.

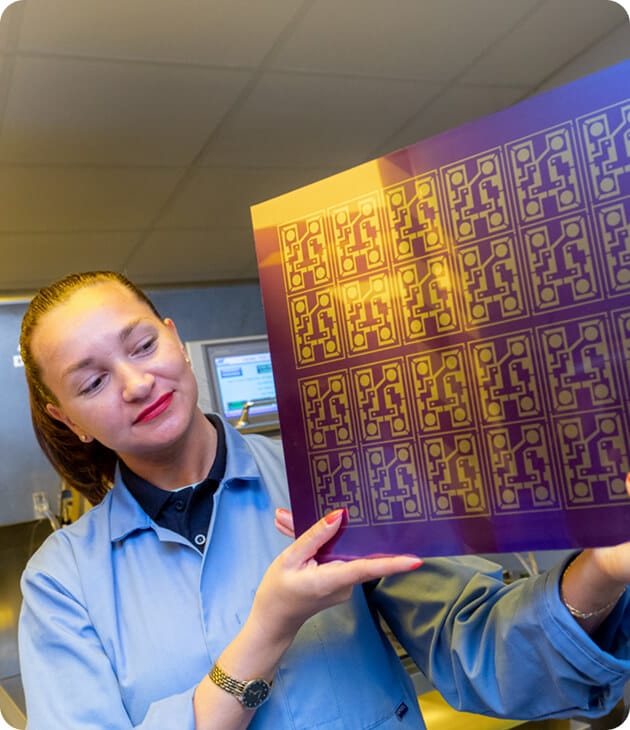

Unique Titanium Etching Process

ACE has developed a new, unique, safer titanium etching process that takes chemical etching titanium to new levels of quality and precision. This is still one of the only safer etchants for use with titanium and is unique to ACE. Learn more about our TiME titanium etching technique.

Processing Speed At Production Scale

ACE has vastly increased the processing speeds and rate of chemical etching titanium. Our titanium etching process has a higher etching capacity, and we are one of the few chemical etching companies in the world that can offer titanium etching on a production scale.

All Metal Grades

ACE’s titanium etching process can produce complex features and geometries in titanium sheets of all grades, including titanium (Alpha) grades 1-4, titanium (beta) grades 5-38, Nitinol and Kapton Coated Titanium. Our titanium etching process does not affect the chemical and mechanical properties of the metal.

Huge Range of Applications

The Titanium etching process has a huge range of applications in a variety of industries, especially in the medical sectors where there is a demand for lightweight etched titanium components used in implants and medical devices such as pacemakers. Find out more about titanium chemical etching for medical devices.

While the conventional, industry standard process of titanium etching can endure several serious drawbacks that make the process unreliable for large volume production. ACE’s development of the TiME titanium etching technique enables them to overcome this problem:

Some of the benefits of our unique titanium etching process include:

and smooth surface etch profile

±10% of material thickness

at no extra cost

aspect ratio possible

from 0.010mm – 1.00mm

up to 280mm x 480mm

personal and environmental risks

Traditionally, Hydrofluoric Acid (HF) has been used as the preferred etchant for chemical etching titanium, because of its ability to remove the titanium oxide layer. However, HF is a highly dangerous chemical and one we will not use! We use a unique, non-HF chemistry developed at our laboratory in the heart of the West Midlands. Find out more about the chemistry of metal etching.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.