Advanced Chemical Etching (ACE), the Midlands based photochemical etching specialist has developed new safe chemistry that it claims will take the etching of titanium to new levels of quality and precision.

Titanium is renowned for its strength and light-weight properties but is difficult to etch due to the fact that it rapidly forms a protective oxidised coating when exposed to air; a coating that is exceptionally hard to dissolve. Traditionally, hydrofluoric acid has been used as the preferred etchant because if its ability to remove this oxide layer but it is a highly toxic material and one to be avoided if possible.

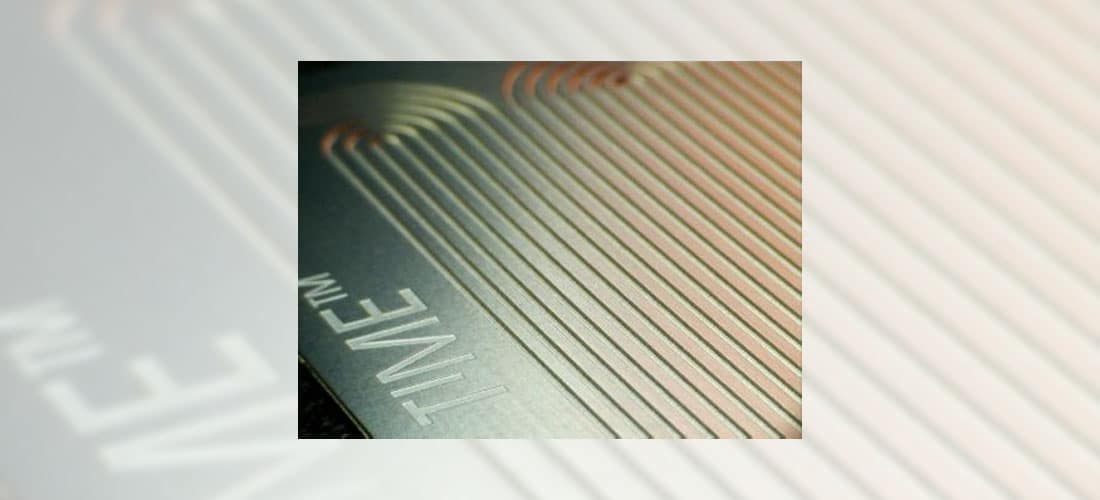

Working closely with Wolverhampton University in a Knowledge Transfer Partnership (KTP), ACE had developed a new process chemistry that it claims is both safe to use and offers superior results. Called TiME (Titanium Molecular Etching) the process is said to be faster and more controllable than the traditional process while offering outstanding precision with sharp, well-defined features and crisp edges.

With a reported 77 tonnes of titanium being used in every Airbus 380, the TiME process is thought likely to be of great benefit to the aviation industry as well as other emerging technologies.