Titanium mesh cranioplasty is becoming increasingly popular for patients with large cranial defects caused by traumatic injuries, iatrogenic injuries and congenital defects. Advanced Chemical Etching (ACE) has developed a chemical process for producing these meshes quickly and without resorting to the traditional and potentially hazardous Hydrofluoric acid chemistry in the production process.

Titanium is the material of choice for cranial and craniofacial implants because of its unmatched biocompatibility and corrosion resistance. It is very resistant to mechanical forces and has 45% less mass than steel material with the same physical properties. A further benefit is that Titanium is radiolucent and permits the safe examination in MRI high field; useful for the longer term patient follow-up.

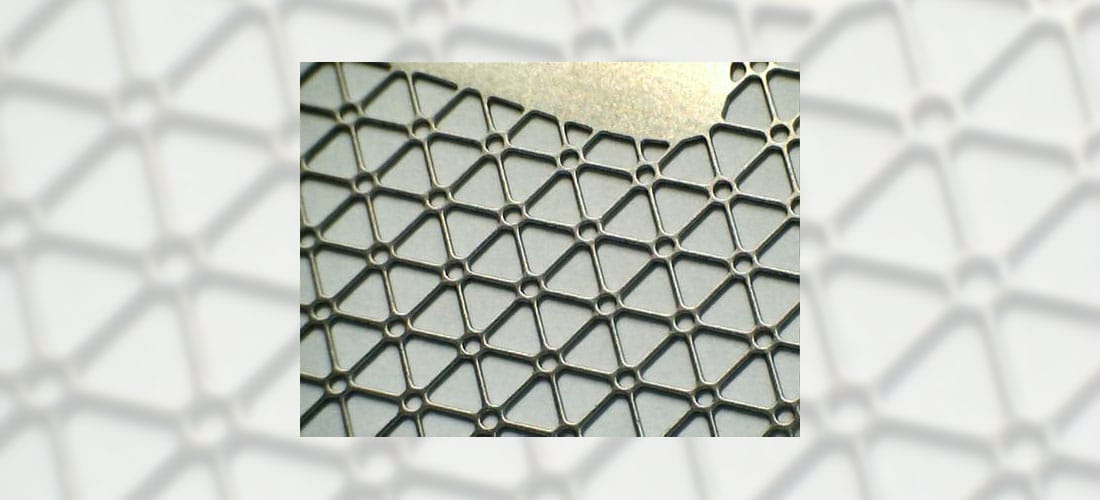

Advanced Chemical Etching can produce bespoke etched cranial mesh implants quickly and economically with its new TiME™ molecular etching process. Parts produced are clean, burr-free and stress-free and having been produced in an ambient process, suffer no work hardening or thermal distortion. As each implant is produced individually, designs can incorporate continuous edges and specific attachment features at no extra cost.