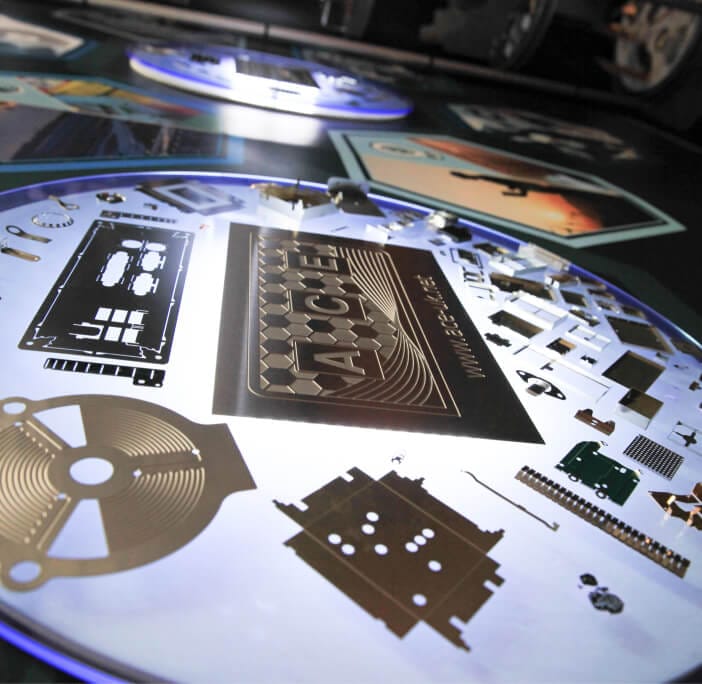

If you’re new to metal etching, this is your gateway to everything you need to know. From what the process actually is, to what kinds of parts can be made, and how ACE can help bring your ideas to life - we’ve broken it down in simple, practical terms.

New to etching? No worries. Whether you're exploring manufacturing options or just curious how it all works, this page breaks it down step by step - with helpful links to learn more as you go.

A precise, stress-free way to cut complex metal parts.

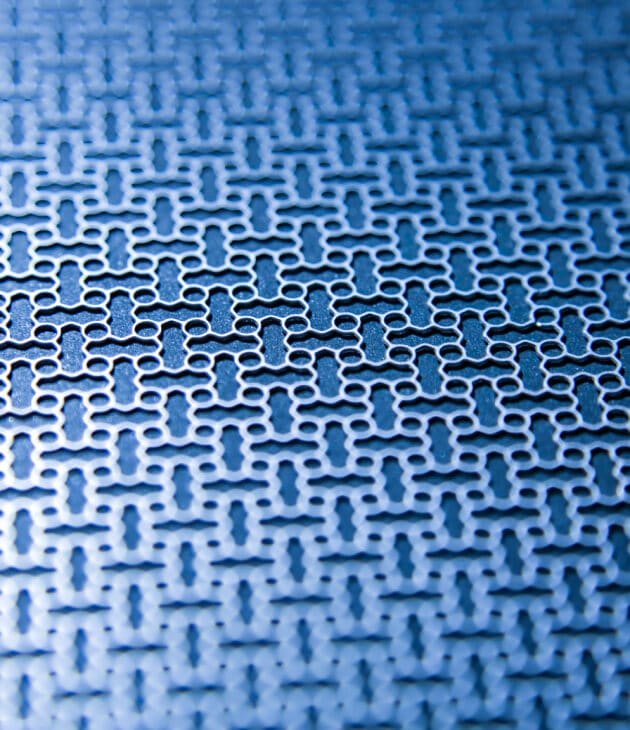

Metal etching (also known as photo chemical etching or photochemical machining) is a highly precise method of producing complex, burr-free components by chemically dissolving selected areas of metal. Rather than using drills, lasers, or punches, the process uses a light-sensitive mask to define the part shape, then applies a controlled chemical etchant to remove unwanted material.

This technique is ideal for producing intricate parts, such as fine filters, connectors, or shields, especially from thin or delicate metals that may deform under traditional cutting methods.

Whether you're developing a new product or just exploring manufacturing options, metal etching offers an affordable, accessible path to precision.

A smarter choice for precision parts, without the drawbacks of traditional methods.

If you've used or considered processes like laser cutting, stamping, or CNC machining, you might be wondering: how is chemical etching different—and why choose it?

Unlike mechanical or heat-based methods, chemical etching uses no physical force and no cutting tools. Instead, it uses a clean, controlled chemical process to remove material through a patterned mask. The result? High-precision parts with no stress, no burrs, and no costly tooling.

No tooling required – so design changes are quick and affordable

No heat or force – your metal won’t warp, bend, or crack

Works with delicate, thin materials other processes struggle with

Ideal for small batches and prototypes – no high setup costs

Fast turnaround – ACE can deliver parts in as little as 48 hours

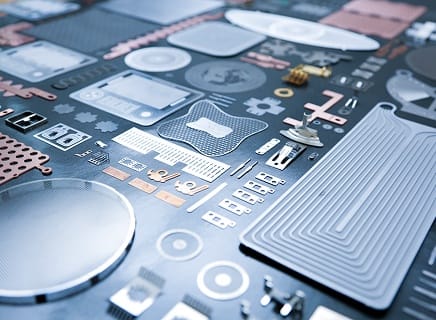

From tiny filters to flexible electronics—etching enables all kinds of parts.

One of the biggest advantages of chemical etching is its ability to produce detailed, high-precision parts in thin metal, without distortion or mechanical stress. This makes it perfect for all kinds of applications where accuracy and complexity matter.

Whether your part is small and intricate or large and layered, etching gives you design freedom without the limits of traditional cutting methods.

for aerospace and electronics

for fluid control or ventilation

used in electrical assemblies

for automotive and energy sectors

thin metal circuits for medical and industrial use

including lead frames and precision foil designs

nameplates, badges, and more

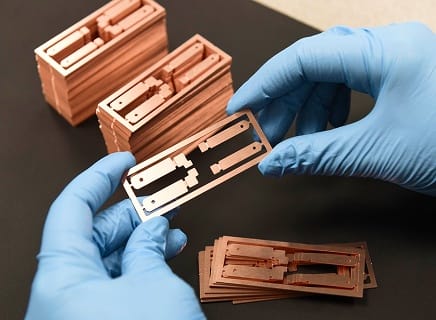

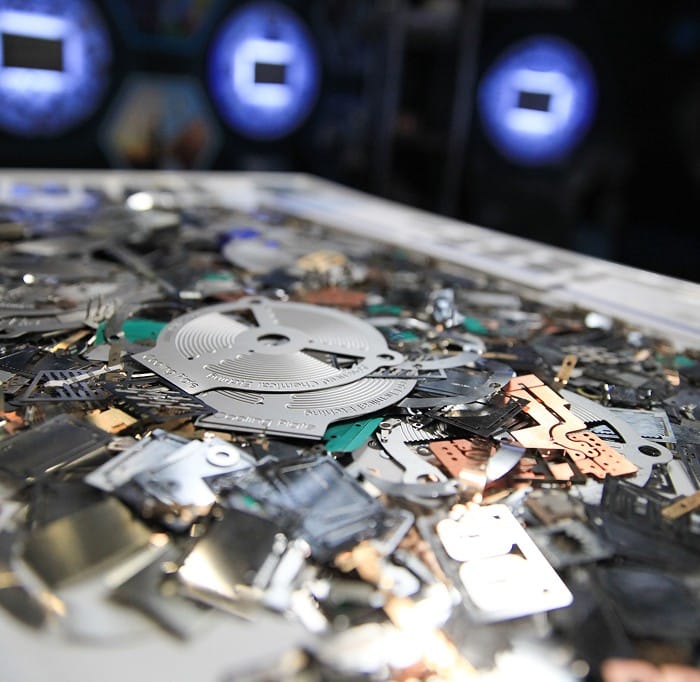

From stainless steel to copper alloys, etching works with a wide range of metals.

Chemical etching is compatible with many types of metal, making it a flexible option for engineers, product developers, and innovators working across industries.

Whether you’re designing something lightweight, conductive, corrosion-resistant, or ultra-thin, there’s likely a metal we can work with and we’re happy to advise if you’re unsure.

From drawing to delivery, etching is simpler than you might think.

You don’t need to be an engineer or manufacturing expert to get started with chemical etching. The process is clean, precise, and much more straightforward than mechanical or heat-based methods. Here’s a quick overview of what happens once you’ve got a design in mind:

No complicated software needed - we accept simple file formats and offer help if you need it.

You don’t need to have advanced CAD tools or engineering software to get started.

At ACE, we make it easy to submit your design—whether it’s a detailed drawing or just an idea on paper.

We Accept

Helpful Tips For First-Time Submissions

If you’re not sure whether your file is ready, don’t worry. Our engineering team will check it and let you know if anything needs adjusting before production begins. We can also help with basic tweaks or feedback on design-for-etching considerations.

Go Deeper:

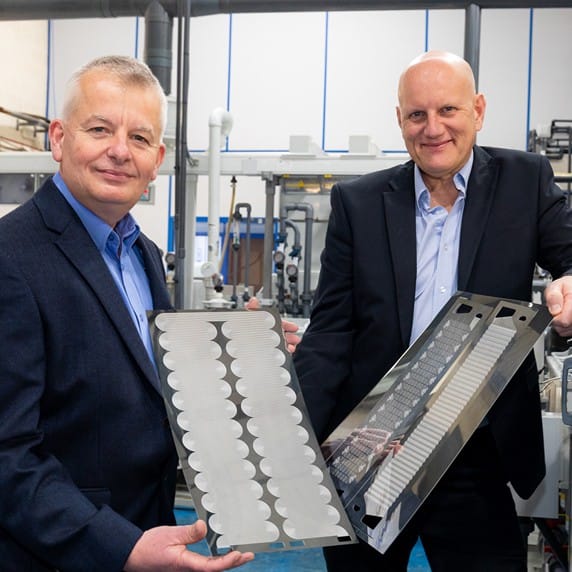

Meet the experts.

Choosing the right partner matters - especially when you're working with a process you're new to. At ACE, we combine specialist knowledge with a supportive, collaborative approach. Whether you're prototyping your first product or sourcing parts for a larger project, our team is here to help at every step.

We’re not just here to manufacture - we’re here to make sure your part works as intended, performs under pressure, and gets to you on time.

in precision chemical etching

for guidance and optimisation

fast prototyping, and scalable production

aerospace quality standards

aerospace, medical, electronics, and more

Certified processes.

Consistent results.

Trusted by industry leaders.

At ACE, quality isn’t just a checkbox - it’s built into every stage of our process. From first-off prototypes to high-volume production runs, we operate within internationally recognised standards to ensure every part meets specification, every time.

Quality Management

Aerospace Quality Management

Environmental Management

Across aerospace, defence, and electronics sectors

All production batches are fully documented

In-process and final inspection is performed using precision measurement tools

We offer first article inspection (FAI) and PPAP documentation on request

Batch samples can be retained for validation and future reference

Whether you're supplying into aerospace or high-reliability electronics, our in-house quality systems ensure compliance and repeatability at every scale.

You don’t need to know everything - we’re here to help.

Getting started with a new manufacturing process can feel overwhelming, especially if it's your first time. But with ACE, you’re not expected to have all the answers. Whether you have a rough idea, a simple sketch, or just a few questions - we’re ready to support you.

Our team works with designers, startups, R&D teams, and curious newcomers every day. We’ll explain what’s possible, help you choose materials, and offer design feedback if needed. No jargon, no pressure - just practical advice and quick answers.

We’ll help you understand your options, avoid common mistakes, and move forward with confidence.