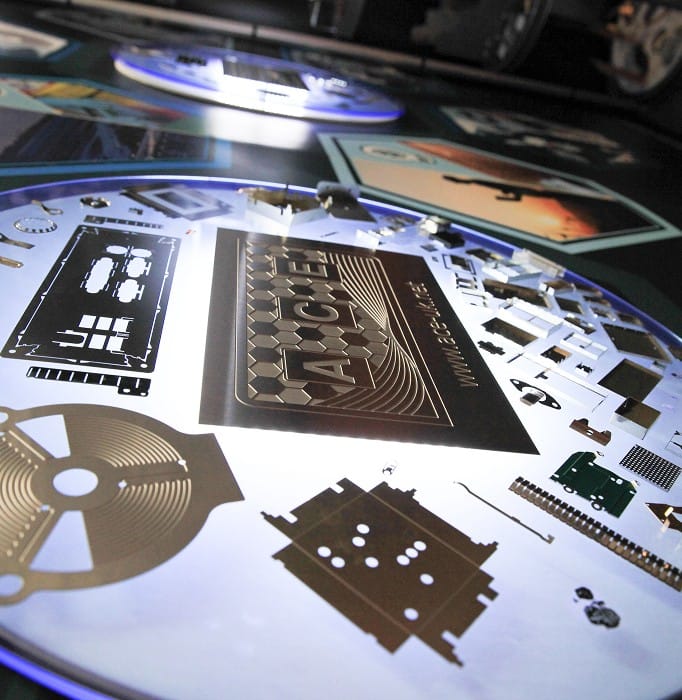

ACE manufactures a wide range of F1 and automotive components for luxury and premium vehicle (tier 1 and tier 2) suppliers across the UK and Europe.

Components we produce for Automotive and F1 include busbars, connectors, safety-critical ABS braking, fuel system management devices and high-end speaker grilles.

Driving Innovation In Electric Vehicles

ACE prides itself on helping to drive the evolution of the automotive industry with the development of the next generation of new (EV) electric vehicles.

Transforming Formula 1 Concepts Into Reality

We also undertake the development of groundbreaking ideas created in the fertile minds of Formula 1 designers and engineers.

We are producing components ranging from battery interconnects, fuel cell plates, cooling plates, kinetic energy recovery system components & electric vehicle bus bars.

We can offer our experience in metals and processes to help customers keep costs down during the development stage. Investment in new state-of-the-art machining centres at our sister business ACE Forming has delivered faster turnaround times and more capacity.

This is having a major impact on the sector and ACE is already developing cooling plates, motor laminations and fuel cell plates to take advantage of these new opportunities.