Client : Confidential – Leading Developer of Compact Fuel Cell Systems for Aerospace and Military Applications

Challenge : The client required lightweight, corrosion-resistant bipolar plates for use in portable and airborne proton exchange membrane (PEM) fuel cells. Traditional graphite or stainlesssteel plates either added excessive weight or were too costly to manufacture at scale with the required precision and channel complexity.

Key challenges:

• Achieve precise micro-channel geometries to optimize hydrogen and oxygen flow.

• Reduce component weight without sacrificing electrical conductivity or durability.

• Minimize production costs while enabling scalability for prototyping and lowvolume production.

Solution: Photo-Etched Aluminium Bipolar Plates

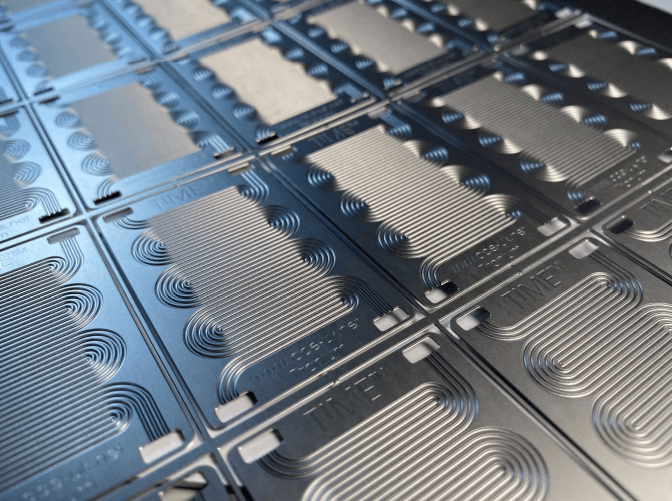

The engineering team proposed the use of photo-etched aluminium bipolar plates, utilizing precision chemical etching (using the unique and innovative process developed by ACE) to create intricate flow field designs on both sides of thin aluminium sheets.

Material Chosen

Aluminium 1000 and 6000 series grades – selected for:

Photo-Etching Process Overview

1. Design: CAD flow field patterns for optimized gas distribution.

2. Masking: Apply photoresist and expose via digital photo tooling.

3. Etching: Chemically etched to ±25 µm precision, with matching front and back flow fields.

4. Post-processing: Plates were cleaned, coated with a protective conductive layer (e.g., gold or carbon-based), and tested for sealing and performance.

Performance Highlights:

• Achieved over 30% reduction in stack weight, critical for aerospace application.

• Improved hydrogen utilization due to more consistent channel geometry.

• Successfully scaled up to 1,000 units with <4% defect rate.

• Allowed for rapid design iterations—new plate designs were turned around within days.

Conclusion

Photo-etched aluminium bipolar plates proved to be a superior alternative to traditional graphite or machined stainless-steel plates for low-weight, high-precision PEM fuel cells. The combination of material properties, high precision structuring, and scalable production makes this approach ideal for emerging sectors such as drones, electric aviation, and portable military power systems.

Next Steps

Based on this success, the client is exploring:

• Integration into other fuel cell stacks

• Alternative coating systems to reduce cost while maintaining corrosion resistance

• Extension to metal-air battery technology

Client: Leading Fuel Cell Stack Manufacturer (Confidential)

Industry: Clean Energy / Fuel Cell Technology

Component: Titanium Bipolar Plates

Manufacturing Process: Photo Chemical Etching

Background: Fuel cell technology is rapidly advancing as a clean and efficient energy solution. Central to Proton Exchange Membrane (PEM) and other types of fuel cells are bipolar plates, which function as current collectors, separators, and gas flow channels. With the demand for lightweight, corrosion-resistant, and high-performance fuel cells, titanium has emerged as a preferred material due to its excellent corrosion resistance, strength-to-weight ratio, and biocompatibility.

However, titanium's high hardness and chemical inertness pose significant machining challenges—especially when precision, micro-scale features are required.

Challenge:

The client required high-volume production of titanium bipolar plates featuring:

• Microchannel flow field designs (depths: 250–300 µm; widths: <700 µm)

• Tight tolerances (±50 µm)

• No burrs or deformation

• Corrosion resistance for harsh fuel cell environments

• Cost-effective production for scaling

Traditional machining methods (CNC milling, stamping, laser cutting) resulted in:

• Tool wear and increased cost

• Micro-burr formation

• Distorted microchannels due to thermal or mechanical stress

• Limited design flexibility

Solution: Photo Chemical Etching

The project team turned to photo chemical etching, a subtractive manufacturing process that uses digital tooling to transfer intricate designs onto a photoresist-coated titanium sheet, followed by selective chemical etching utilising the bespoke titanium etching process developed by ACE

Key Benefits:

• Stress-free process: No mechanical or thermal distortion

• High precision: Capable of producing micro-scale channels and features

• No burrs: Eliminates need for secondary finishing

• Rapid prototyping: Fast turnaround for design iterations

• Material integrity: Preserves native corrosion resistance of titanium

Process Overview:

1. Photo tooling: CAD-designed microchannel patterns plotted on film

2. Material Selection: Commercially Pure (CP) Titanium Grade 2 (0.5 mm thick)

3. Pre-Cleaning: Sheets chemically cleaned to prepare for resist coating

4. Photoresist Application: Laminated and exposed to UV through the film

5. Developing: Areas on the plates that require etching have coating removed

6. Etching: Etchant selectively removes exposed titanium

7. Resist Removal: Resist stripped from etched plates then cleaned.

8. Inspection: Dimensionally Burr-free, high-fidelity microchannel structures

Results:

| Metric | Specification | Achieved |

|---|---|---|

| Channel Depth | 250–300 µm ±50 µm tolerance | Achieved |

| Channel Width | <700 µm | Consistent profile |

| Plate Flatness | <30 µm | Achieved |

| Edge Quality | Burr-free | Yes |

| Yield | >98% | Achieved |

• Delivery time Reduced by 60% compared to CNC prototyping

• Cost per unit Reduced compared to CNC prototyping

• Design change lead time Reduced from 2 weeks to 5 days

• No tooling wear, Enabling high repeatability for 5,000+ units

Conclusion: This case study demonstrates the superiority of photo chemical etching for producing titanium bipolar plates for advanced fuel cell applications. It enabled the client to achieve precision, repeatability, and cost-effectiveness at scale while maintaining the intrinsic properties of titanium. As fuel cells become more widespread across automotive, aerospace, and stationary power sectors, photo etching offers a scalable pathway for manufacturing high performance titanium components.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.