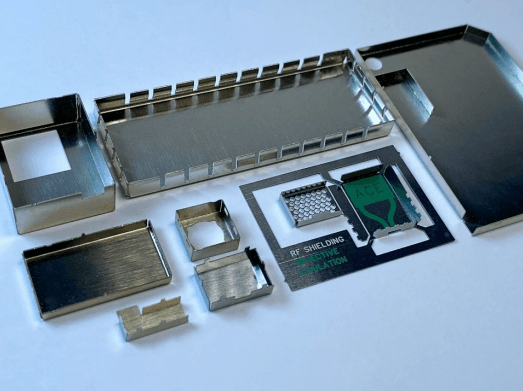

To reduce Radio Frequency Interference (RFI) and increase Electro-Magnetic Interference (EMI) protection using Photo Etched & Formed Screening Cans in electronics settings.

Customer Overview

Customer: A leading manufacturer of compact wireless communication devices

Industry: Electronics

Product: High-frequency communication modules

Challenge: EMI shielding in densely populated PCB layouts without sacrificing space or design flexibility

As the need for device miniaturisation increased, the customer's latest line of modules encountered significant EMI cross-talk between components, affecting signal clarity and causing performance reduction. Traditional manufacturing processes such as stamped shielding cans posed several problems:

Limited Design Flexibility

Difficult to accommodate intricate & complex layouts and multicompartment shielding.

Higher Hard Tooling Costs

Expensive hard tooling and time-consuming to adapt designs for multiple product variants.

Suboptimal Heat Dissipation

Stamped shields lacked airflow slots or custom openings without additional tooling or machining costs.

Etched & Formed Screening Cans

The customer partnered with Advanced Chemical Etching Limited (ACE) to transition from stamped screen cans to photo etched and formed screening cans.

Implementation

Design Phase:

Prototype Validation:

Production Rollout:

“The shift to etched screening cans was transformative. Not only did we eliminate persistent EMI issues, but the flexibility and cost savings from rapid prototyping accelerated our development cycles significantly.”

Lead Engineer, Wireless Division

By transitioning to etched & formed screening cans, the customer gained a competitive edge in both product performance and manufacturing efficiency. This approach is now being standardised across their upcoming device families.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.