Advanced Chemical Etching (ACE) has developed new innovative process technologies for the manufacture of plate heat exchangers, cooling plates and cold plates for the chemical, petrochemical, linear motor, electronics, automotive, electric vehicle and aerospace cooling sectors.

What Is A Heat Exchanger?

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids.

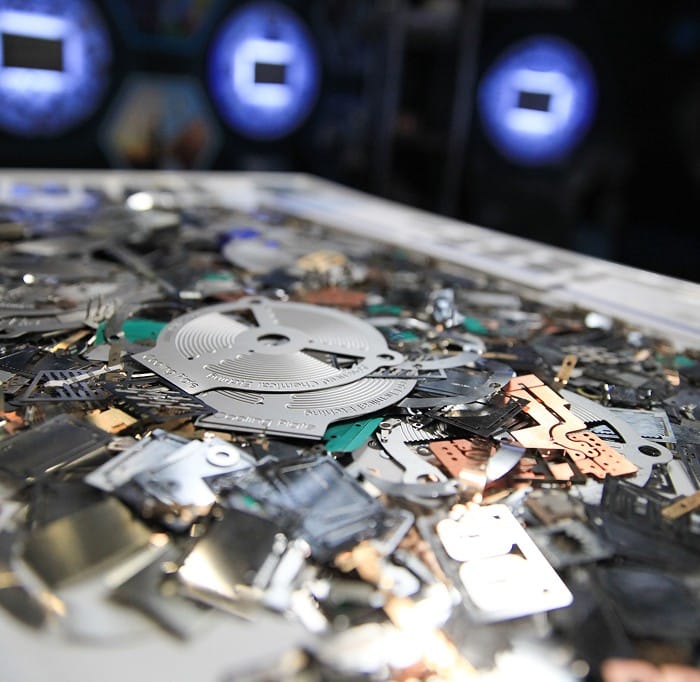

What Metals Are They Produced In?

Manufactured by the ACE photo etching process from Stainless Steel, Aluminium, Titanium, Copper or Inconel©

What Are The Benefits Of Etching?

Photo etching leaves no mechanical or thermal stress, unlike CNC machining, stamping and laser machining, which can compromise planarity (flatness).

After The Etching...

The photo etched plates are stacked and diffusion bonded, diffusion brazed or brazed together to make the heat exchanger.

Low set-up costs and fast lead times make etching a go-to process in batch sizes of one to multiple millions.

The tooling for etching is digital, low-cost and can be modified quickly.

No heat or force is used when etching so mechanical properties remain unaltered and parts are free from stresses and burrs.

As component features are etched at the same time, part/feature complexity is not an issue.

Flat blanks etched then diffusion bonded or brazed.

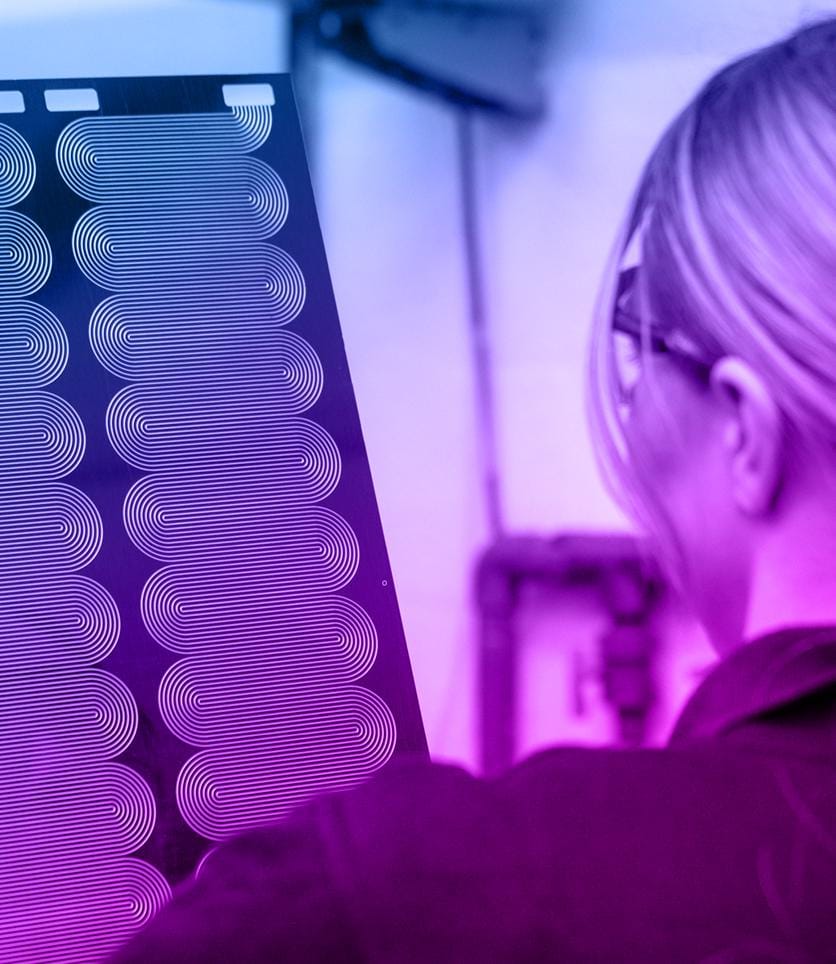

Micro-Etched Fluid Flow Channels

Heat Exchangers are produced as flat plates with precision micro-etched fluid flow channels in either the top or both the top and underside surfaces. This is also known as printed circuit heat exchangers (PCHEs), as the process of manufacture is the same process as printed circuits hence the product name.

Space & Weight Benefits

Much smaller than shell and tube heat exchangers delivering excellent space and weight benefits, plate heat exchangers can have a pressure capability of 600 bars (9000 psi) while coping with temperatures ranging from cryogenic to 900°C (1650°F). More than two process streams can be incorporated in a single unit and the requirement for piping and valves dramatically reduced.

A Wide Range Of Materials

The association of chemical etching and diffusion bonding processes into a single product allows the use of a wide range of materials, which, subsequently, allows the use of a variety of clean fluids in the heat exchanger (including corrosive ones).

More Functionality

Reaction and mixing can also be incorporated in the plate heat exchanger design, economically increasing functionality in a single unit.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.