Advanced Chemical Etching (ACE) specialises in photo etching medical alloys, such as Stainless Steel (including 300 series and 400 series), Titanium alloys, Nitinol and Cobalt-Chromium based alloys. The photo etching process delivers a very complex profile and parts will be burr-free, unlike conventional profiling processes.

Biocompatible dental implants can have extremely complicated features and burr-free edges which traditional machining technologies find difficult to achieve.

All are burr-free with no rough edges that could interfere with mating parts.

The ACE process supplies thousands of eye ophthalmic surgery blades every month, using medical grade Stainless Steel.

Extremely complex, stress-free titanium membranes and micro contact springs used in hearing aid microphones and PCBs can be etched burr-free to very tight profile tolerances.

ACE manufactures extremely intricate titanium anode and cathode battery grids used in batteries contained within implantable defibrillators.

We also manufacture micro-sized screening cans used in pacemakers, which feature an electrical insulator selectively applied to reduce arcing.

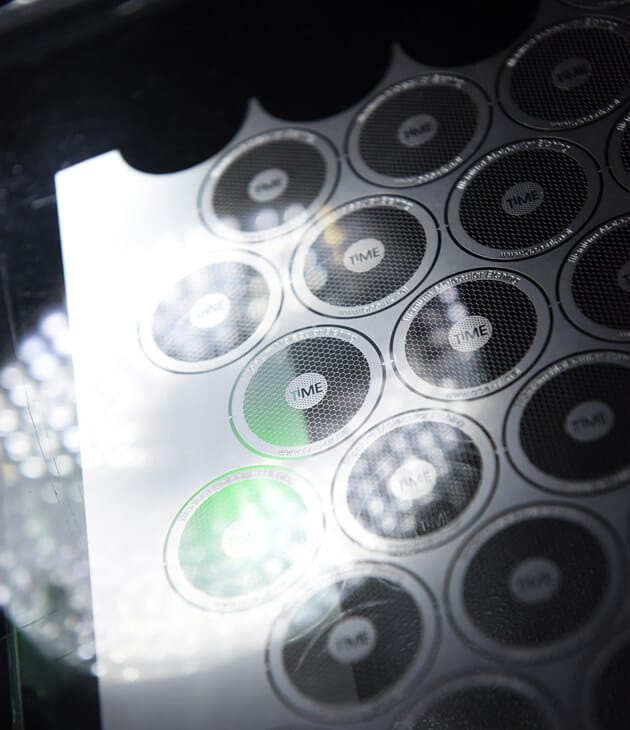

A wide range of 2D and 3D electronics components (including lead frames, EMI/RFI shielding, connectors, contacts, biosensor springs and meshes) can be photo etched burr and stress-free, with clean profiles and no heat-affect. This makes them ideally suited to the requirements of the medical sector.

Using digital tooling, we prototype mesh designs quickly, adapt them at little cost and have them production-ready in a matter of hours.

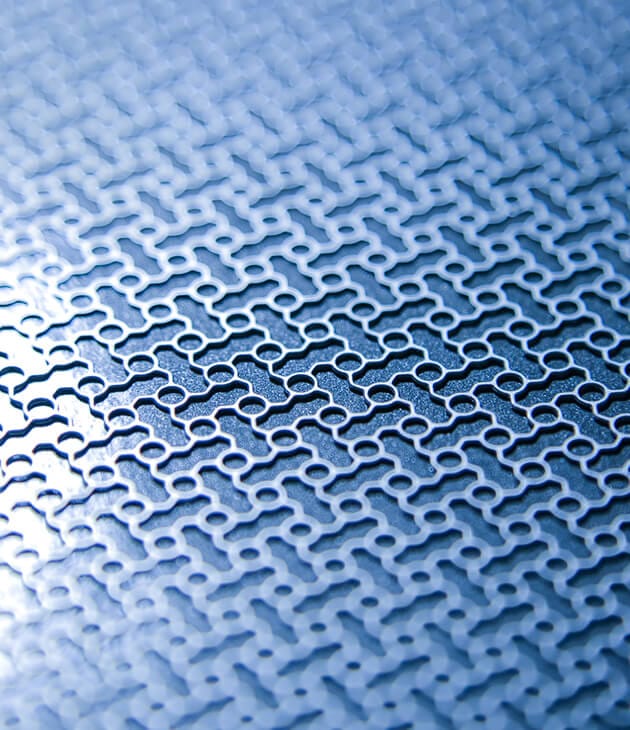

ACE photo etch craniomaxillofacial implants in all grades of titanium (alpha & beta).

Highly complex meshes can be produced in thickness from 0.025mm to 1.00mm.

The photo etching process does not cause any work hardening, stress, distortion and is burr free.

Etched stepped countersinks can be produced in one operation and can be included at no extra cost.

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.