Welcome to your tailored resource for advanced chemical etching. Whether you’re designing for aerospace, electronics, or precision components, this hub connects you with key technical specs, material capabilities, and production insight. Use it to explore tolerances, materials, and workflows - or head straight to quoting and collaboration.

Explore detailed technical insights, material options, tolerances, and workflows designed for engineers who know what they need.

Know what’s possible - before you start designing.

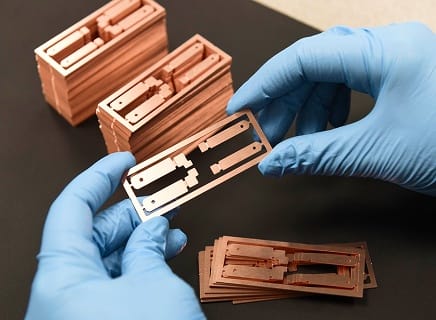

When precision matters, knowing the limits of the process is essential. Our chemical etching capabilities are engineered to support high-accuracy applications across sectors like aerospace, medical, and electronics.

We offer tight tolerances, clean edge finishes, and high repeatability, all without the stresses introduced by mechanical machining. With no need for hard tooling, you can move from prototype to production faster - and adapt designs without penalty.

typically ±0.025mm of material thickness

from 0.01mm to 1.5mm

suitable for volume production

fast, cost-effective prototyping and revisions

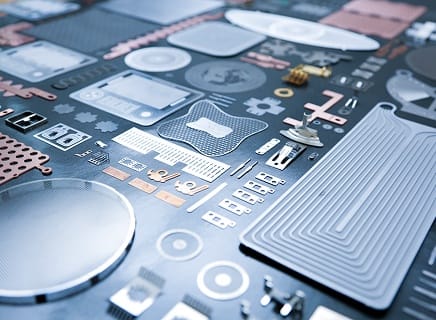

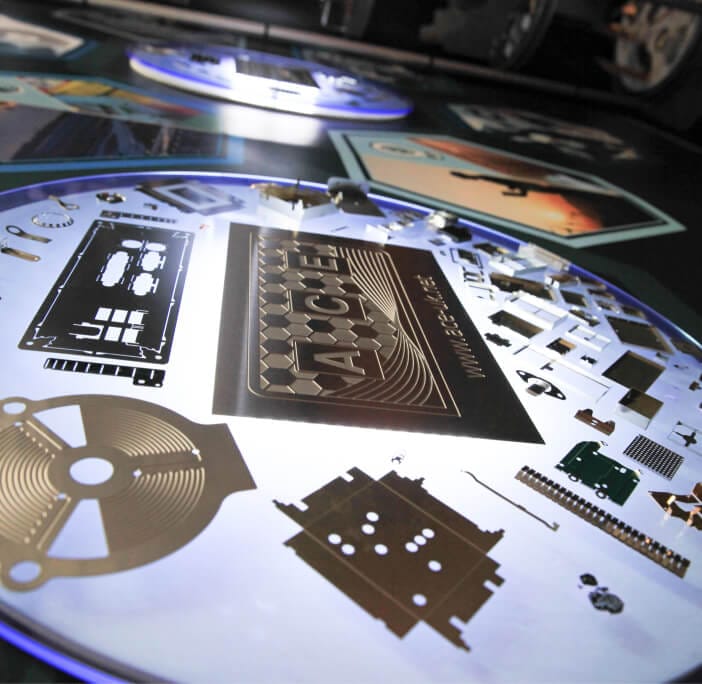

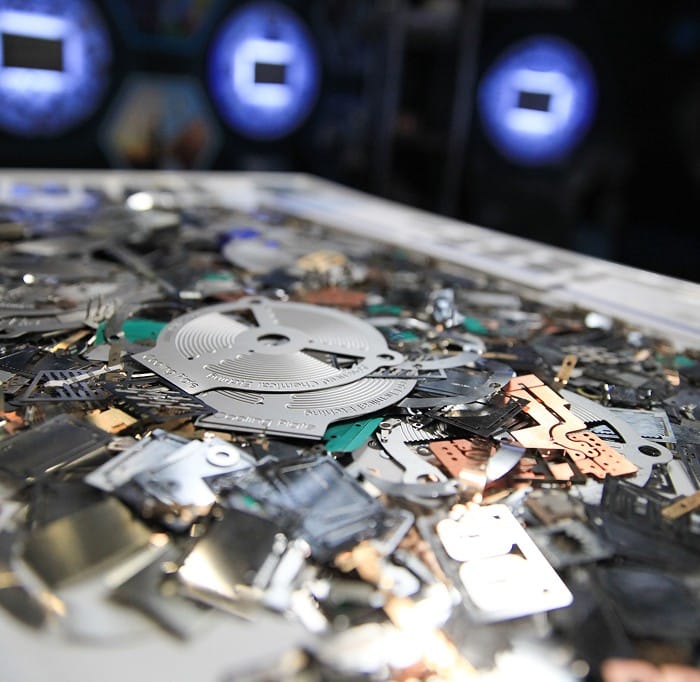

Precision across a wide range of metals—etched to your specification.

ACE offers precision etching across a wide range of metals commonly used in aerospace, automotive, electronics, and medical sectors. Every material is processed using chemical etching techniques that maintain structural integrity - producing clean, stress-free, burr-free results, even on complex or delicate geometries.

Our process supports both standard and specialist metals in varying thicknesses, from prototypes to production-scale runs. Whether you're targeting conductivity, corrosion resistance, weight reduction, or heat performance, our engineers can advise on the best-fit material for your application.

Collaborate with our engineers to optimise your design, before it hits production.

Every successful etching project starts with a well-prepared design. At ACE, we provide technical guidance during the quoting stage to help identify potential improvements and ensure manufacturability from the outset. While we don’t require tooling, certain design considerations - like material thickness, feature complexity, and part layout - can significantly impact precision and cost.

Accepted File Formats:

We accept various types of files. Please include relevant material requirements, critical tolerances, and any key notes. Our engineering team reviews every submission as part of our process - and we’ll reach out if anything can be optimised or clarified.

Need Design Input Or Want To Check Your Files?

From first-off prototypes to repeatable high-volume runs, without tooling delays.

ACE’s chemical etching process is tooling-free, which means you can go from prototype to production without the delays and costs typically associated with hard tooling. Whether you’re developing a new component or refining an existing design, we offer rapid turnaround during early-stage development and reliable scalability for long-term supply.

Our Process Is Ideal For:

What To Expect:

Go Deeper:

At ACE, we combine cutting-edge chemical etching technology with decades of expertise to deliver precision metal components.

Whether you're an experienced engineer, new to metal etching, or just curious about what we do, we’ve got you covered.

Our team regularly works with customers across the following sectors:

EMI/RFI shielding, precision filters, fuel system components

Sensors, battery connectors, fluid control plates

Diagnostic devices, heating elements, surgical instrumentation

Lead frames, flex circuit components, contact springs

Fine meshes, screens, fluid flow regulators

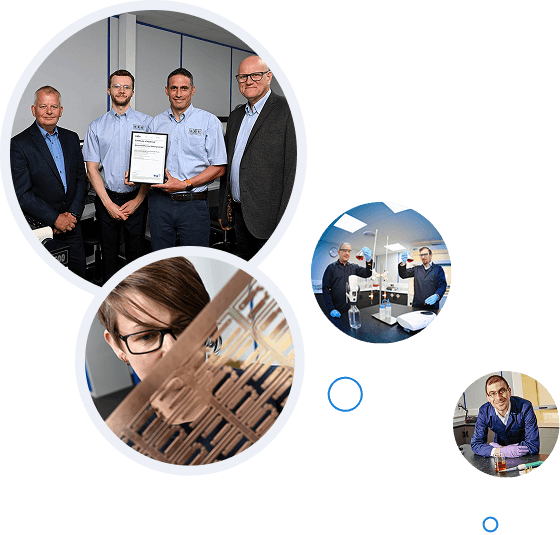

Certified processes.

Consistent results.

Trusted by industry leaders.

At ACE, quality isn’t just a checkbox - it’s built into every stage of our process. From first-off prototypes to high-volume production runs, we operate within internationally recognised standards to ensure every part meets specification, every time.

Quality Management

Aerospace Quality Management

Environmental Management

across aerospace, defence, and electronics sectors

All production batches are fully documented

In-process and final inspection is performed using precision measurement tools

We offer first article inspection (FAI) and PPAP documentation on request

Batch samples can be retained for validation and future reference

Whether you're supplying into aerospace or high-reliability electronics, our in-house quality systems ensure compliance and repeatability at every scale.

Behind every precision-etched component is a team of experts dedicated to pushing the boundaries of manufacturing. Meet the specialists who ensure quality, innovation, and technical excellence at ACE.

Join us at the UK’s leading manufacturing and electronics show.

Southern Manufacturing & Electronics!

3rd & 5th February 2026 10:00 AM - 5:00 PM

Stand: C190

Farnborough International Exhibition Centre